19/33kV medium-voltage IEC 60502-2 overhead bundled cable (ABC) is a medium-voltage overhead power cable designed for urban power distribution networks, rural electrification, and long-distance industrial overhead lines. Compared to traditional exposed overhead conductors, the conductors of this cable are bundled together with insulation and shielding layers, offering higher safety, reliability, and easier installation.

Table of Contents

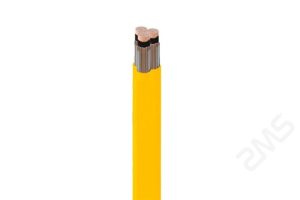

ToggleZMS manufactures 19/33kV medium-voltage ABC cables in strict accordance with IEC 60502-2 and relevant power specifications. It uses stranded aluminum conductors insulated with XLPE cross-linked polyethylene and is suitable for three-phase overhead power distribution systems up to 33kV.

Cable Construction & Appearance

MV ABC 19/33kV cables are supplied in a compact, round bundled form for installation on overhead power poles or towers.

- Conductor: Stranded compacted aluminum (Category 2) or aluminum alloy, round, smooth surface, high conductivity.

- Conductor Shielding: Extruded semi-conductive layer covering the conductor surface.

- Insulation: XLPE cross-linked polyethylene insulation, suitable for continuous operating temperatures up to 90°C, with high dielectric strength and aging resistance.

- Insulation Shielding: Extruded semi-conductive layer covering the XLPE insulation surface.

- Metallic Shielding: Copper wire shielding or copper tape shielding, aluminum wire shielding is also available upon request.

- Sheath (Optional): Black UV-resistant HDPE or MDPE outer sheath providing additional mechanical and environmental protection.

- Bundling: Typically 3 insulated phase cores twisted together for easy installation on power poles; compact bundles with or without neutral/ground wires, depending on design.

- Color: Black outer surface.

Construction Parameters (Example for 3×95mm² & 3×150mm²)

| Item | Rated Voltage kV | Conductor Cross-Section mm² | Approx. Conductor Diameter mm | Nominal Insulation Thickness mm | Nominal Screen Thickness mm | Metallic Screen Area mm² | Approx. Overall Diameter (Bundle)mm | Approx. Cable Weight kg/km | Max. DC Resistance at 20°C Ω/km | Test Voltage (5 min) kV |

| 3×95 mm² | 19/33 | 95 | 11.0 | 8.0 | 1.2 | ≥16 | 65–75 | 2,200–2,700 | 0.32 | 76 |

| 3×150 mm² | 19/33 | 150 | 13.5 | 8.0–8.5 | 1.2 | ≥25 | 75-90 | 2,800–3,500 | 0.206 | 76 |

ZMS can supply other cross-sections (e.g. 50, 70, 120, 185, 240 mm²) and customized screen design according to project specifications.

Note: The following is a typical data range for reference. The exact design can be customized according to utility requirements.

Technical Characteristics

Maximum Conductor Temperature:

Normal operation: 90°C

Emergency overload: 130°C

Short circuit: 250°C (maximum 5 seconds)

Frequency:

50Hz or 60Hz

Installation Method:

Aerial installation on poles, walls, or truss structures

Minimum Bending Radius:

Typically ≥ 15 times the cable outer diameter

Standards Compliance:

IEC 60502-2 – Extruded insulated power cables and accessories rated from 6 to 30 kV

Other utility and national standards are available upon request

Applications of 19/33kV MV ABC Cable

MV IEC 60502-2 ABC 19/33kV cables are widely used in:

Urban and Suburban Distribution Networks

- Overhead three-phase medium-voltage lines in cities and towns

- Replacement of old bare conductors to increase safety and capacity

Rural Electrification and Long-Distance Feeders

- Overhead MV feeders for villages, farms, and remote communities

- Reduced right-of-way requirement compared to bare conductors

Industrial and Mining Areas

- Overhead supply to mining sites, industrial plants, and construction sites

- Suitable where ground cabling is difficult or costly

Coastal and Harsh Environments

- Corrosion-resistant design using aluminum and PE, suitable for coastal, humid, and polluted zones

Temporary or Semi-Permanent Power Lines

- MV overhead lines for project sites, wind farms, and solar power connection lines

Key Features

1. Enhanced Safety: Compared to bare conductors, the insulation and bunding of medium voltage aerial bundled cables reduce the risk of phase-to-phase faults and accidental contact, and also lower the likelihood of short circuits caused by branches or animals.

2. High Reliability: The XLPE insulated medium-voltage conductors offer excellent dielectric strength and long-term thermal performance, reducing outage rates and minimizing maintenance needs for power companies.

3. Cost-Effective Installation: Simplified hardware and accessories allow for easier and faster pole-mounted installation, reducing the required clearances between phases and between the cable and buildings, saving space and construction costs.

4. Strong Environmental Adaptability: The outer surface is resistant to UV radiation, ozone, and moisture, making it suitable for outdoor environments in various climates, performing exceptionally well in polluted, rainy, and coastal conditions.

5. Reduced Line Losses: Lower failure rates result in fewer outages, better voltage regulation, and improved power quality for end users.

6. Customized Designs and Accessories: ZMS offers various conductor sizes, shielding designs, and sheath options. We can also provide a complete set of medium-pressure air control (MV ABC) system accessories, including connectors, clamps, terminals, and terminals.