The H05VVC4V5-K is a low-voltage shielded control cable conforming to European HAR standards for equipment control and signal transmission. Rated at 300/500V, it features electromagnetic compatibility (EMC) protection, oil resistance, and flame retardancy. The cable uses finely stranded copper conductors, clearly numbered core wires, and oil-resistant PVC inner and outer sheaths, making it suitable for dry, humid, and damp indoor environments. Its high-coverage tinned copper braided shield provides stable signal transmission and control for industrial equipment. It has passed multiple certifications, including CPR, CE, and TÜV, and its quality and compliance are widely recognized in the European market.

Table of Contents

ToggleThis cable is commonly used for internal wiring within equipment and connections between control cabinets and sensors. It is particularly suitable for industrial applications requiring flexible installation, strong anti-interference capabilities, and long service life.

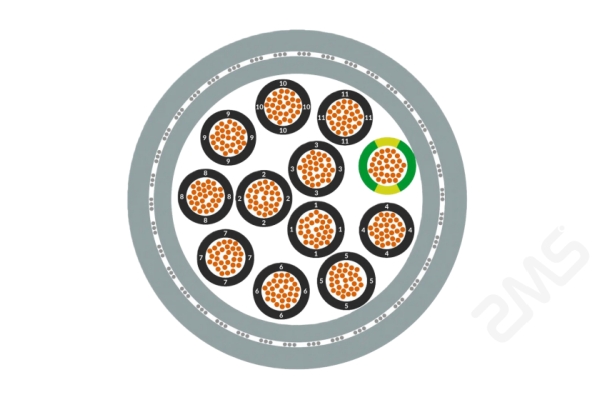

H05VVC4V5-K Cable Structure

| Structure | Description |

| Conductor | Extra fine bare copper, multi-strand stranded wire, conforming to DIN VDE 0295 Class 5 / IEC 60228 Class 5. |

| Core Insulation | Special PVC insulation, conforming to relevant DIN VDE/EN standards. |

| Core Identification | Black core wire; 3 or more cores, including a green/yellow protective ground wire. |

| Stranding/Lay | Multi-core layered stranding. |

| Inner Sheath | PVC inner sheath. |

| Screen | Tin-plated copper braided shielding, with a braided coverage of approximately 85%. |

| Outer Sheath | Oil-resistant PVC outer sheath, gray in color. |

Application

Industrial Automation: Used for equipment control and signal transmission in industrial machinery, machine tools, assembly lines, conveyor lines, and production lines.

HVAC Systems: Connects control circuits for heating and air conditioning systems.

Special Industrial Environments: Suitable for damp or liquid-contact environments such as breweries, bottling plants, and car washes, as well as industrial environments containing chemicals and greases.

Instrumentation and Control Engineering: Used for fuel pumps, measuring and control equipment, instruments, and other signal transmission applications requiring immunity to electromagnetic interference.

Installation Requirements: Suitable for indoor fixed installation (moderate mechanical load), supports no tensile loads and occasional, non-continuous bending; not suitable for outdoor applications.

Technical Parameters

| Parameter | Detail Values |

| Operating Temperature Range | Fixed Installation: -40℃ to +70℃; Occasional bending: -5℃ to +70℃ |

| Min. Bending Radius | Fixed installation: 6 × cable outer diameter (5 × for some specifications); Occasional bending: 20 × cable outer diameter (10 × for some specifications) |

| Flame Retardant | Compliant with IEC 60332-1-2 / DIN EN 60332-1-2 standards |

| Oil Resistance | Compliant with EN 50363-4-1: TM5 and IEC 60811-404 standards |

| Chemical Resistance | Resistant to chemical and grease corrosion |

Structural Parameters (Common Models)

| Number of cores × cross section | Typical Outer Diameter(mm) | Copper Content(kg/km) | Weight(kg/km) |

| 4×0.5 mm² | 7.2–8.4 | 19–26 | 70–90 |

| 7×0.5 mm² | 8.3–9.6 | 28–37 | 90–120 |

| 12×0.75 mm² | 11.0–12.5 | 54–68 | 150–200 |

| 18×1.0 mm² | 13.5–15.0 | 110–130 | 240–300 |

| 25×1.5 mm² | 16.5–18.2 | 190–220 | 380–450 |

Product Advantages

Compliant with European Certifications: Certified by HAR Harmonisation, CPR, and CE, meeting multiple European standards including EN 50525-2-51 and VDE, enjoying high recognition in the European market.

Strong Electromagnetic Shielding: The tinned copper wire braided shielding layer provides approximately 85% shielding coverage, low transfer impedance, and effectively isolates external electromagnetic interference, ensuring stable transmission of measurement and control signals, suitable for EMC-sensitive environments.

Excellent Environmental Resistance: The outer sheath is made of oil-resistant PVC material, conforming to TM5 standards, resistant to grease and chemical corrosion; it also possesses flame-retardant properties, suitable for dry, humid, and damp indoor environments, including water-oil mixture scenarios.

Flexible and Durable: The conductor is Category 5 soft-stranded copper wire, offering excellent bending performance, supporting occasional bending scenarios, suitable for both fixed installations and occasional movement scenarios, and boasting high mechanical strength.

Clear Marking: The core wires feature a black background with white numerical coding, conforming to VDE 0293-334 standards, facilitating identification of core wire functions during installation and maintenance.

Environmentally Friendly & Safe: The production materials are free of cadmium and silicon, and contain no substances that are harmful to the wetting properties of the paint surface. They comply with environmental standards such as RoHS, making them safer to use.