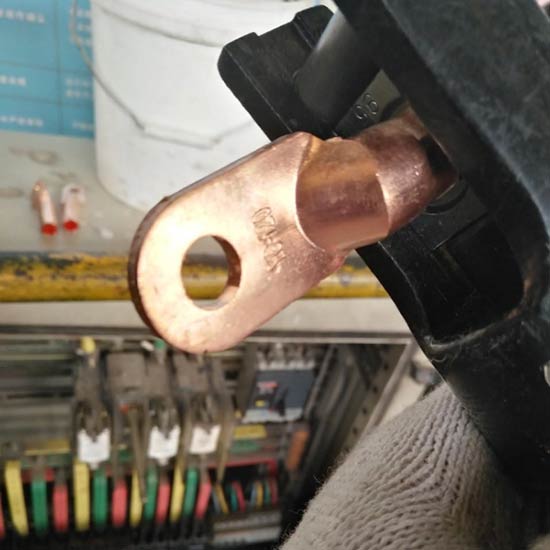

Cable Lugs

The cable lugs function is to connect the cable to the electrical equipment, between cables, surface, or mechanical equipment. You can buy various industry-standard cable lugs at ZMS. ZMS has a wide range of cable lugs for terminating or connecting cables, like DTL bimetallic aluminum terminal lugs, DL cable terminal lugs, DT copper terminal lugs, etc.

- High welding strength

- High electrical performance

- High electrical and corrosion resistance

- Long service life

- Not easy to break, high safety performance

- 99.95% oxygen-free high conductivity copper tube

Cable Lugs Types

The types of cable lugs vary depending on the raw material of the product, copper, aluminum, or plastic and are generally used in industries such as construction, automotive, energy and utilities, manufacturing, and processing. ZMS produces the following table of wire lugs and chart:

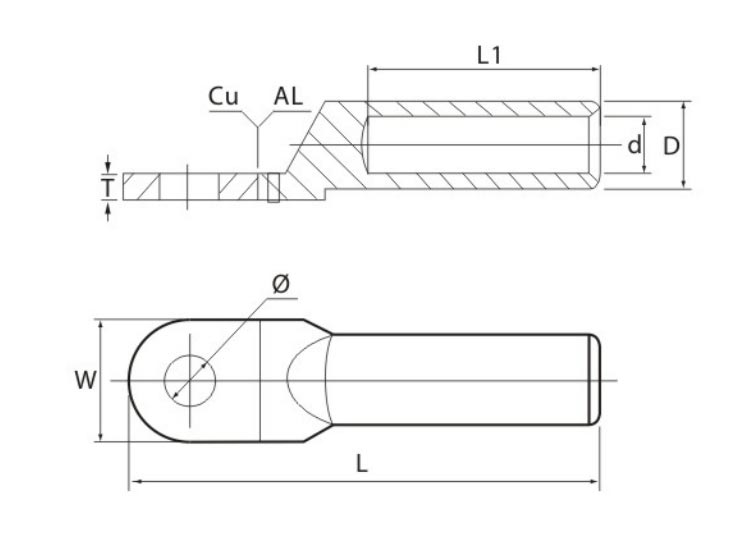

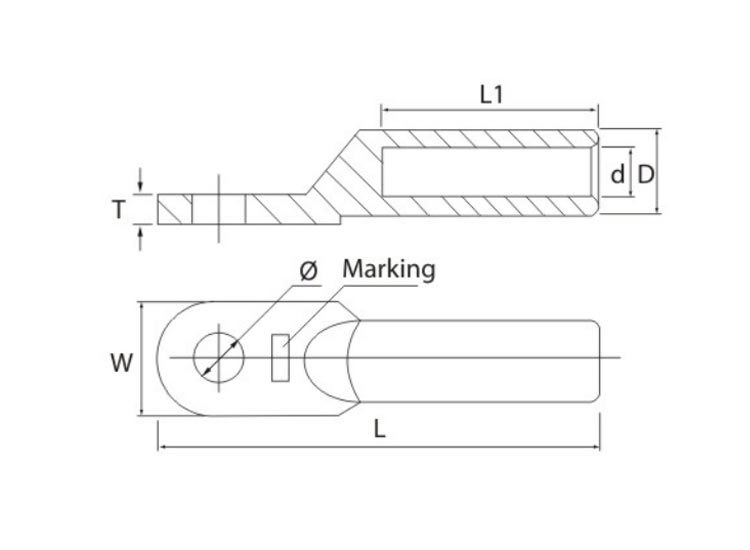

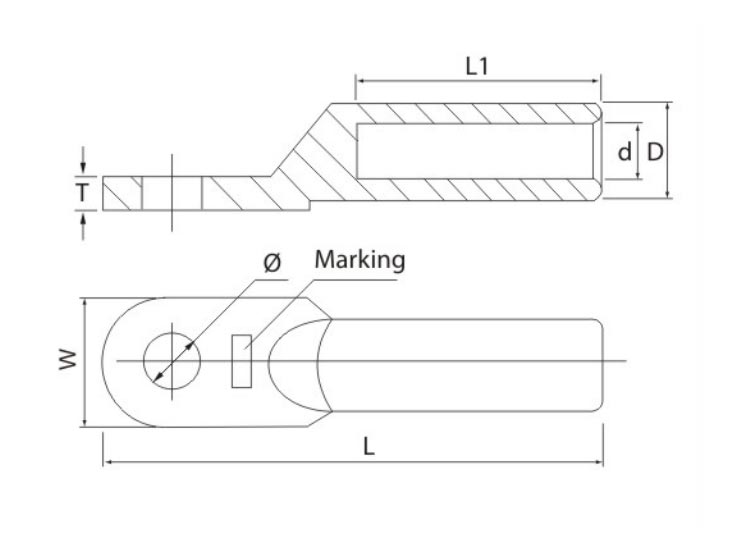

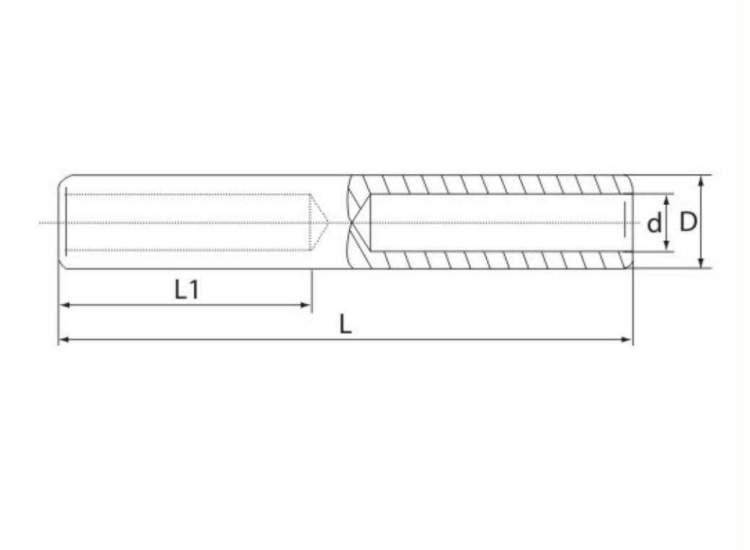

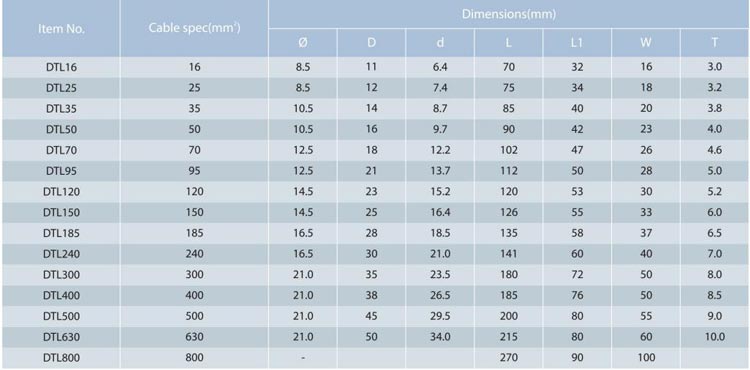

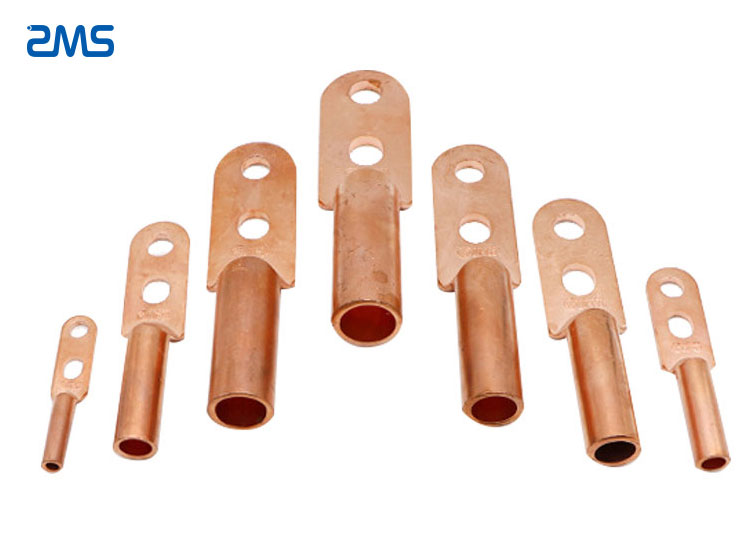

DTL Copper-Aluminum Terminal Lugs are suitable for excessive connection between aluminum core cables of power distribution devices and copper ends of electrical equipment. Our production of bimetallic copper cable lug not only looks beautiful but also has good conductivity. Usually, wiring is also safer, in the power distribution cabinet distribution, electrical industry, machinery industry with more.

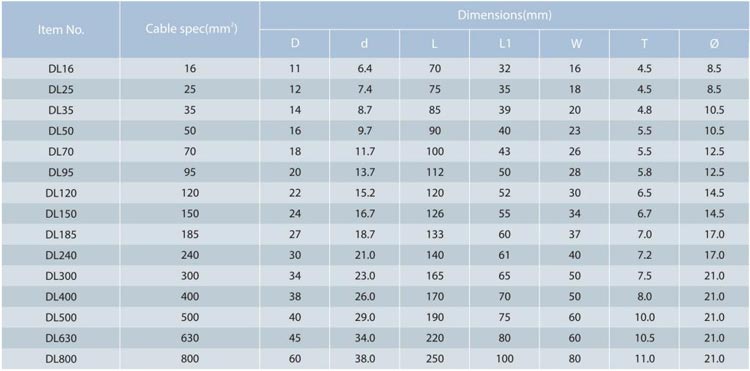

DL Aluminum Terminal Lugs are used to connect aluminum core cables to the aluminum ends of electrical equipment. The cable aluminum terminal lug products use friction welding process manufacturing, with high weld strength, good energizing performance, resistance to galvanic corrosion, long service life, and so on.

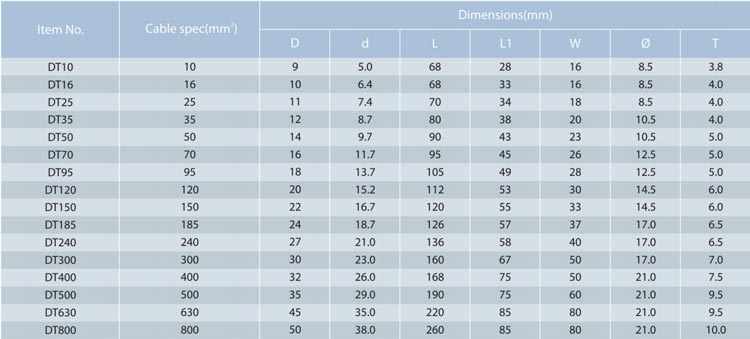

DT Copper Terminal Lugs are used to connect copper core cables to the copper ends of electrical equipment. The product is commonly used in cable end connection and renewal. Can make the cable and electrical connection more solid, and more secure. It has the characteristics of high weld strength, good energizing performance, anti-electrochemical corrosion, and long service life. It is a commonly used material in the construction, electrical industry, machinery industry, etc.

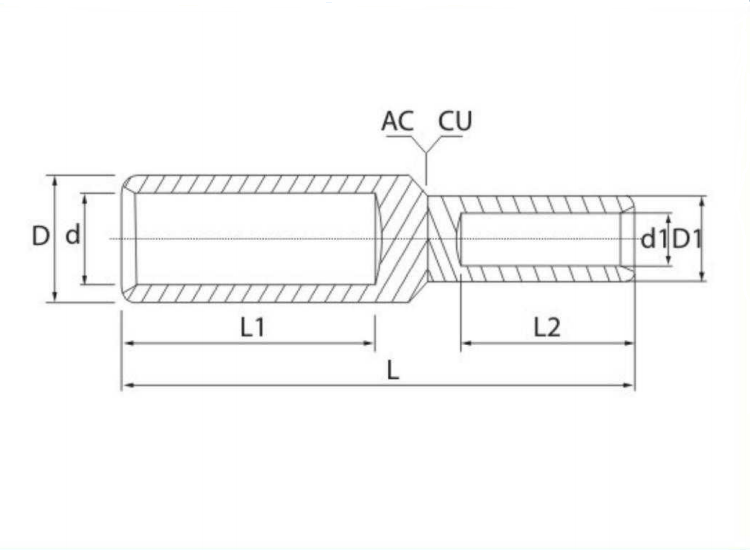

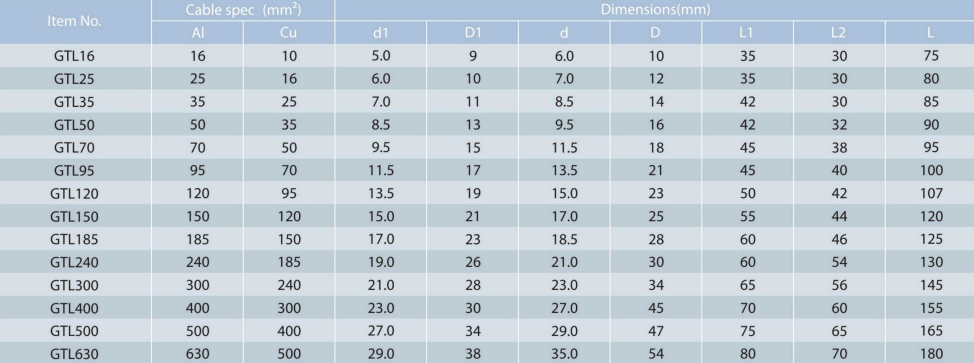

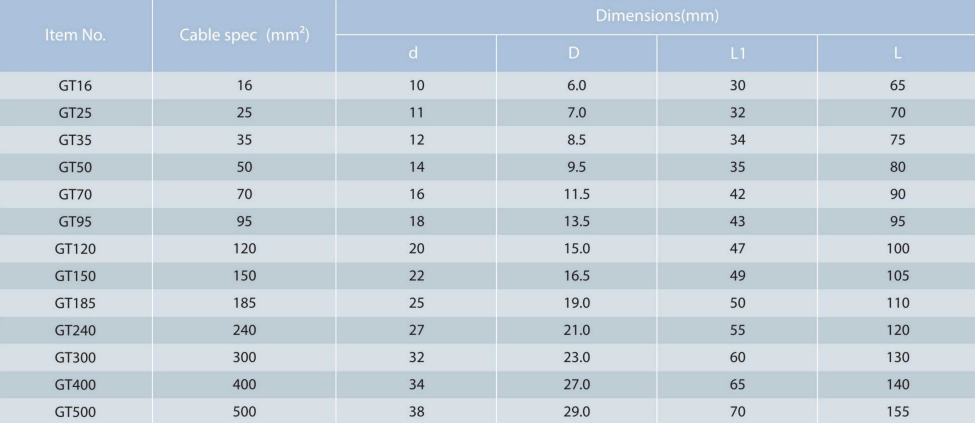

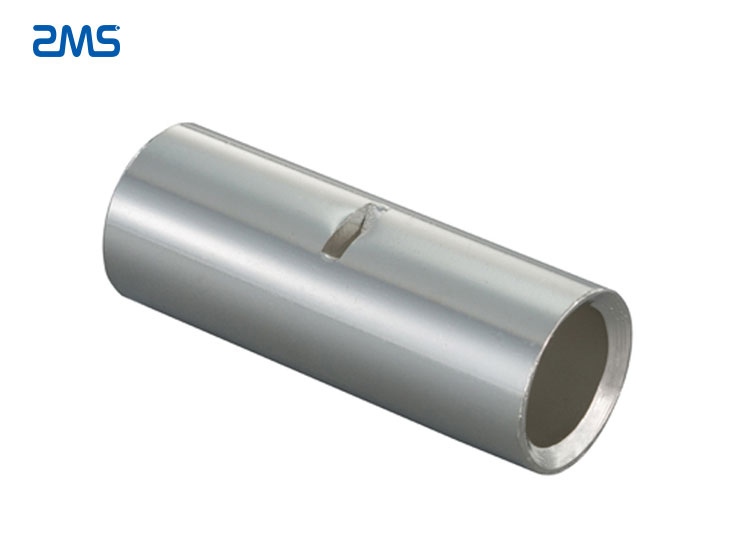

Bimetallic Connector (Link) GTL Series are Solid center barriers.

·The links can be designed to join four core aluminum sector conductors to conventional stranded copper conductors.

·Prefilled with jointing compound.

·Friction welded.

·Material: Cu≥99.9%,Al≥99.5%.

The impermeable center barrier to oil or moisture.

Material: Cu≥99.9%.

Surface: Electro tin plated.

The Other Type of Cable Lugs

Cable copper lugs are available in a wide range of types and sizes. If you don’t know how to choose the product you need or can’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, and we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS cable supplier has some quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

The Function of The Power Cable Lugs

- Cable equipment lugs are mainly used for the sub-connection of the outgoing section of the busbar of the substation and the electrical equipment (such as transformers, circuit breakers, isolating switches, wall bushings, etc.).

- Because there are two types of terminals lugs for common electrical equipment, copper and aluminum, and the bus lead is divided into aluminum stranded wire or steel core aluminum stranded wire, the equipment lugs are divided into aluminum equipment lugs and copper-aluminum transition equipment from the material.

- According to the different installation methods and structural forms, equipment lugs are divided into two types: bolt type and compression type. The angles between the double-press down-lead of each type of wire lugs and the terminal of the electronic equipment are divided into 0°, 30° and 90°.

Precautions for Using Cable Lugs

1. Select the appropriate specification model.

2. Select the appropriate lug model according to the wire diameter.

3. Follow the instructions for proper operation during installation to avoid incorrect use.

4. Do not exceed the load capacity of the wire connector.

About ZMS Cable Accessories Manufacturer

- ZMS Cable Group Co., Ltd. is a leading manufacturer and supplier of power cables and cable accessories and heat shrinkable products in global. ZMS company was established in 1990 and now has more than 30 years of development history.

- We always adhere to the competitive strategy of differentiation, internationalization and self-development. We aim to become a leader in the global cable and cable accessories industry. Our products have obtained ISO9001, ISO14001, UL, CSA and KEMA and other international certifications.

- ZMS company relies on excellent product quality, meticulous customer service, and efficient and fast delivery capabilities. We sincerely invite you to cooperate with you to achieve excellent results.

- ZMS factory has imported several large-scale equipment and production lines of power cables and cable accessories from Germany, Hong Kong and Taiwan.

- These production lines have laid a solid foundation for our R&D and quality assurance. Our cable accessories products have a high reputation in the Philippines, UAE, Kenya and other countries and regions.

- We not only produces high-quality cable terminations, but also types of cable insulators, cable lugs, cable clamps and other cable accessories made of top materials.

More Information