NYFGY cables, available in medium and low voltage variations, are PVC insulated, armored with flat steel wire, and reinforced with mechanical protection. They are primarily used in laying environments requiring high mechanical strength, such as underground cabling and industrial equipment installation.

Table of Contents

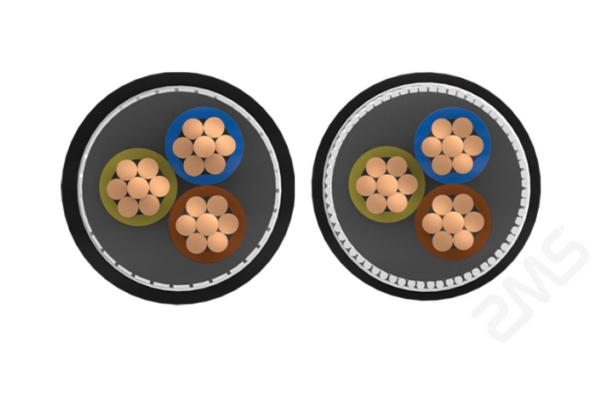

ToggleNYFGY Cable Construction

Component | Material / Description |

Conductor | Stranded copper conductor, Class 2 according to IEC 60228 |

Insulation | PVC (Polyvinyl Chloride) insulation, color coded |

Inner Sheath (optional) | PVC or PE filler for circular cable shape |

Armour | Flat galvanized steel wire armour (FWA) for mechanical protection |

Outer Sheath | PVC outer sheath, black or red color (UV resistant) |

Available & Common Sizes (Examples)

No. of Cores × Cross Section (mm²) | Approx. Outer Diameter (mm) | Weight (kg/km) |

3 × 4 mm² | 18.5 | 520 |

3 × 10 mm² | 22.0 | 850 |

3 × 25 mm² | 27.5 | 1300 |

3 × 50 mm² | 34.5 | 2050 |

3 × 95 mm² | 44.0 | 3200 |

3 × 150 mm² | 52.5 | 4300 |

Technical Datasheet

Rated Voltage (U₀/U):0.6/1 kV or 3.6/6 kV

Test Voltage (AC 5 min):3.5 kV (for 0.6/1 kV type) / 11 kV (for 3.6/6 kV type

Operating Temperature:–5 °C to +70 °C

Short-Circuit Temperature (5 s max):+160 °C

Installation Temperature (min.): –5 °C

Min. Bending Radius:15 × cable outer diameter

Flame Retardancy: IEC 60332-1 compliant

Standard Length:100 m, 500 m, 1000 m (customized on request)

Cores × Cross-Sectional Area (mm²) | Overall diameter appr. mm | Weight appr. kg/km | Current carrying | Current carrying capacity air |

3 x 50 SM | 41 | 3.520,0 | 175 | 165 |

3 x 70 SM | 44 | 4.345,0 | 220 | 205 |

3 x 95 SM | 47 | 5.330,0 | 260 | 250 |

3 x 120 SM | 49 | 6.220,0 | 295 | 285 |

3 x 150 SM | 52 | 7.120,0 | 335 | 325 |

3 x 185 SM | 57 | 8.625,0 | 370 | 380 |

3 x 240 SM | 59 | 9.885,0 | 425 | 430 |

NYFGY Cable Features

Enhanced Mechanical Protection: Flat Wire Armor (FWA) provides superior resistance to compression and impact in buried or mechanically stressed environments.

Stable Electrical Performance: High-quality copper conductors ensure excellent conductivity and low power loss.

Durable PVC Insulation: Offers strong resistance to chemical corrosion, oil, moisture, and UV radiation.

Flexible Installation Options: Suitable for direct burial, pipework, tunnel, or fixed installation in industrial plants.

Cost-Effective and Reliable: Mature design compliant with VDE and IEC standards, widely used in industrial projects in Europe and Asia.

Typical Applications

NYFGY cables are suitable for:

Power transmission and distribution in industrial facilities

Underground cable networks

Power plants and substations

Outdoor installations with mechanical stress risks

Fixed cabling in heavy-duty environments

Infrastructure and building projects

For example, underground cable trenches and mechanical installations require additional mechanical protection.

Standard

IEC 60228

DIN VDE 0271

DIN VDE 0276-603

DIN EN 60228 class 2 (construction)