Thermocouple Cables

Thermocouple cables connect thermocouples to measuring instruments and are widely used in temperature measurement systems across nuclear power, petroleum, chemical, metallurgy, and electric power industries. ZMS Cable is a leading manufacturer offering high-grade stainless steel and special alloy thermocouple wires, steel strip systems, and industrial heating solutions. Our product range includes K-type, J-type, T-type, and other thermocouple cables.

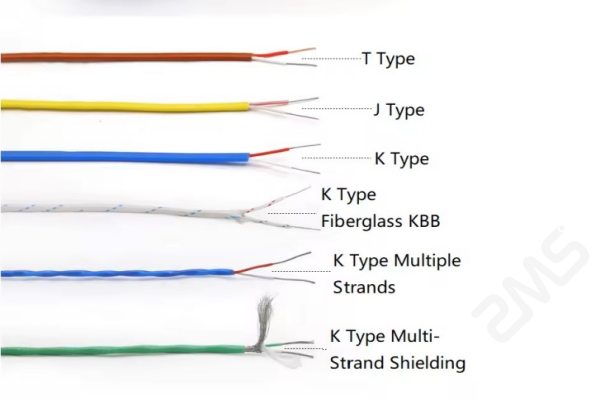

Thermocouple Cable Types

The role of the thermocouple compensation wire cable is to extend the cold end of the hot electrode, i.e., the mobile thermocouple, to connect with the display instrument to form a temperature measurement system. Thermocouple compensation wire is generally used in thermocouples. We can provide 2-wire, 3-wire, and 4-wire thermocouple cables, as well as the best thermocouple cable prices.

Additionally, we offer customization services for thermocouple extension wires. You can provide the following detailed parameters: 1. Conductor size and type. 2. Insulation and sandwich material. 3. Shielding material. 4. color.

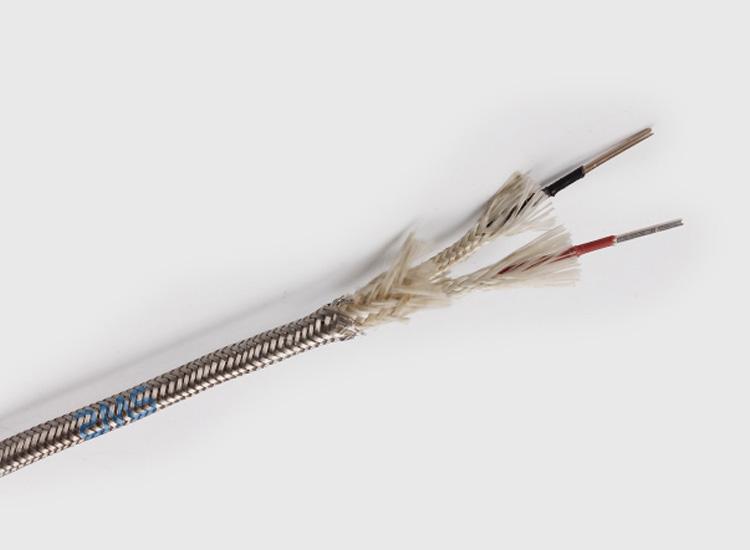

1. FB insulation + FB insulation + SS braid

2. Conductor: NiCr-NiSi

3. Color: Red +, Black –

4. Size: 2*7*0.2mm

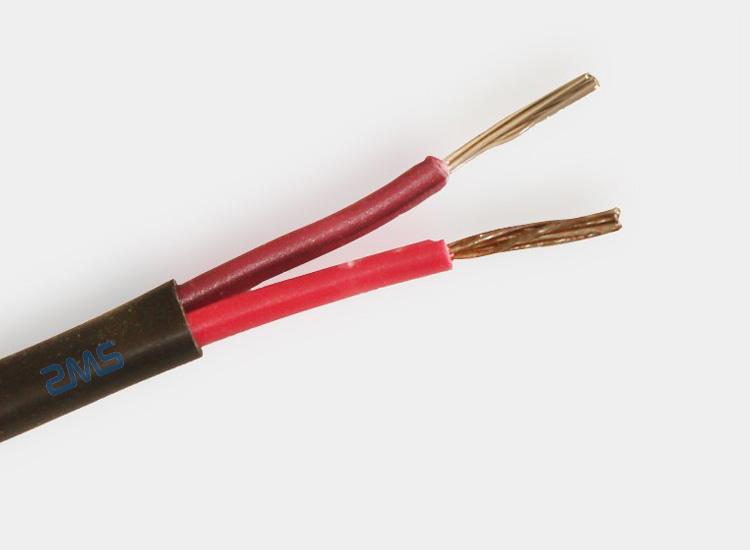

1. PVC insulation + Silicone rubber

2. Conductor: Iron-CuSi

3. Color: Red +, Purple –

4. Size: 2*7*0.5mm

1. PVC insulation + Silicone rubber

2. Conductor: Fe-CuNi

3. Colour: Red +, Purple –

4. Size: 2*7*0.3mm

1. PVC insulation + PVC insulation

2. Conductor: Cu-CuNi

3. Colour: Red +, White –

4. Size: 2*7*0.1mm

1. PVC insulation + Cooper wire braid

2. Conductor: Cu-CuNi

3. Color: Red +, Blue –

4. Size: 2*1mm

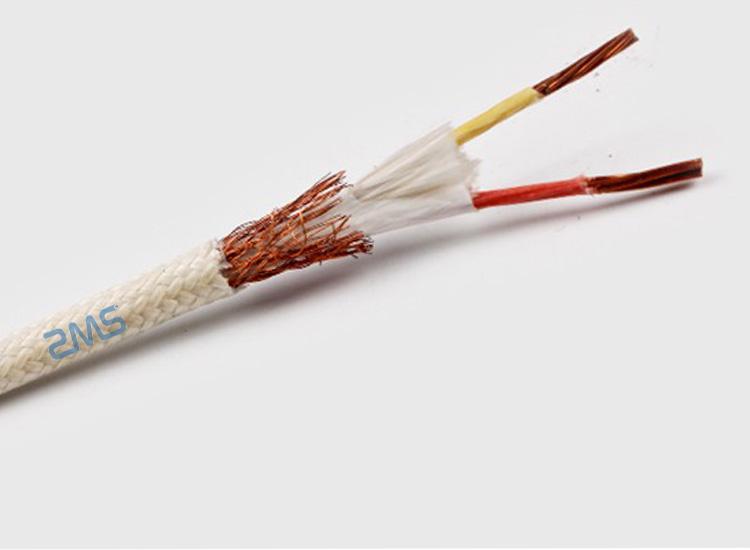

1. FB insulation+Cooper wire braid+FB insulation

2. Conductor: Fe-CuNi

3. Color: Red +, Yellow –

4. Size: 2*7*0.2mm

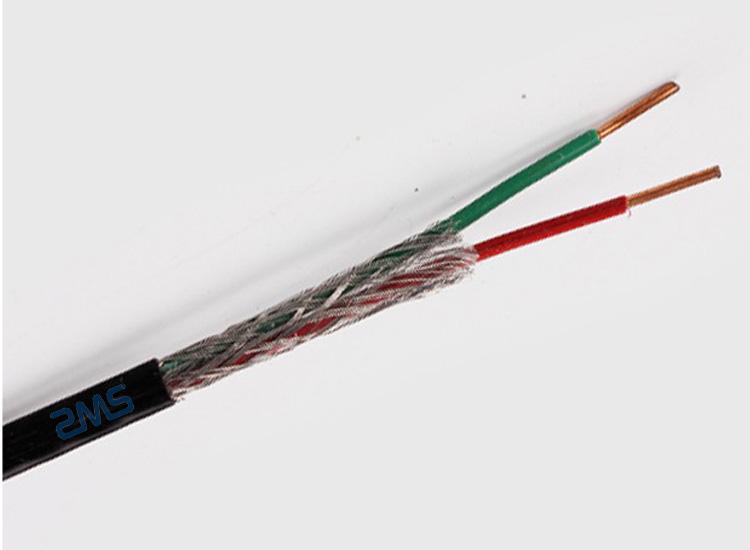

1. PVC insulation+SS braid+Silicone rubber insulation

2. Conductor: Cu-CuNi

3. Color: Red +, Green –

4. Size: 2*7*0.2mm

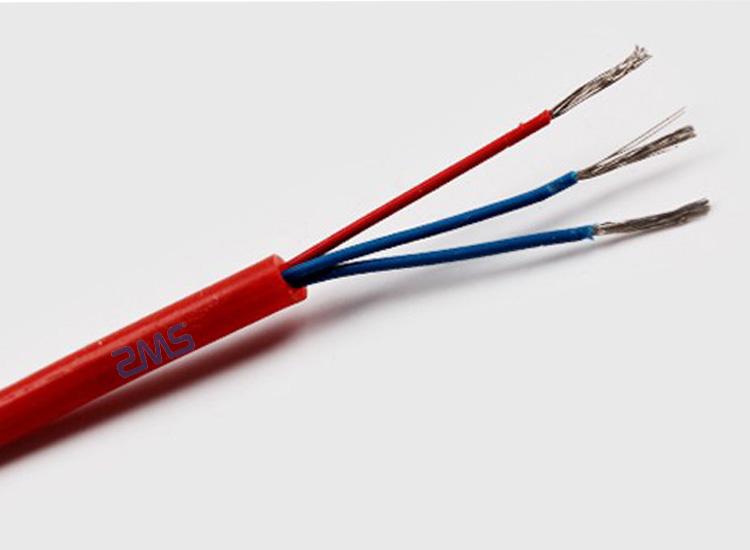

1. PVC insulation + PTFE insulation

2. Conductor: Cu-CuNi

3. Color: Red, Blue, Blue

4. Size: 3*7*0.2mm

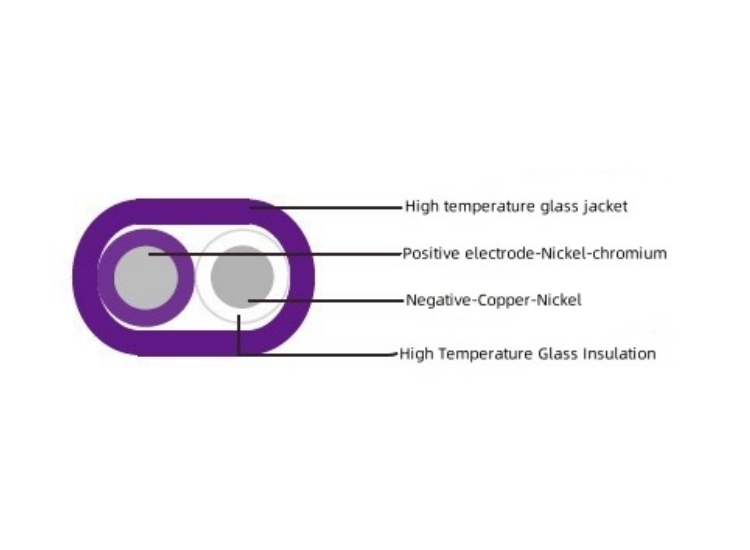

Single Pair Flat High Temperature Glass Insulated Thermocouple Cable

Conductor: Solid. Material depends on type of thermocouple.

Insulation: High temperature glass

Sheath: High temperature glass

Construction: Flat

Color: According to IEC 60584-3

This type of cable is connected to a thermocouple to measure temperature.

Type: K, E, J, N

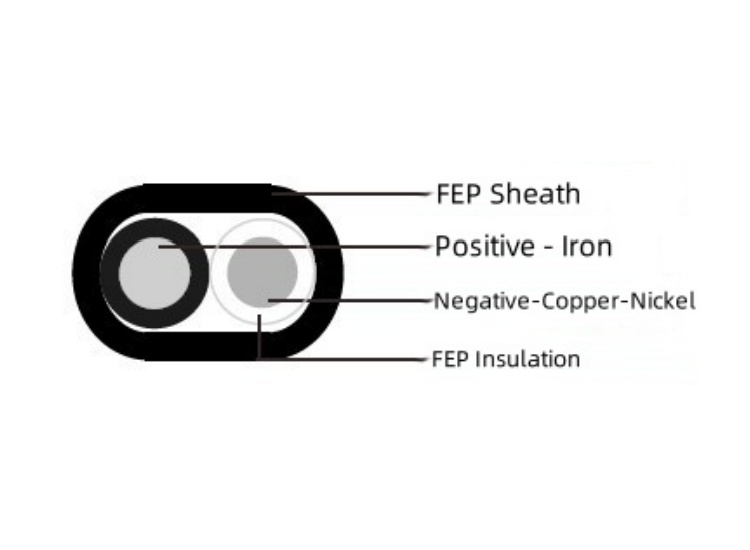

Single Pair Flat FEP Insulated Cable

Conductor: Solid. Material depends on type of thermocouple.

Insulation: FEP

Sheath: FEP

Construction: Flat

Color: according to standard IEC 60584-3

The FEP model has cables that are connected to thermocouples to measure temperature.

Type: K, E, J

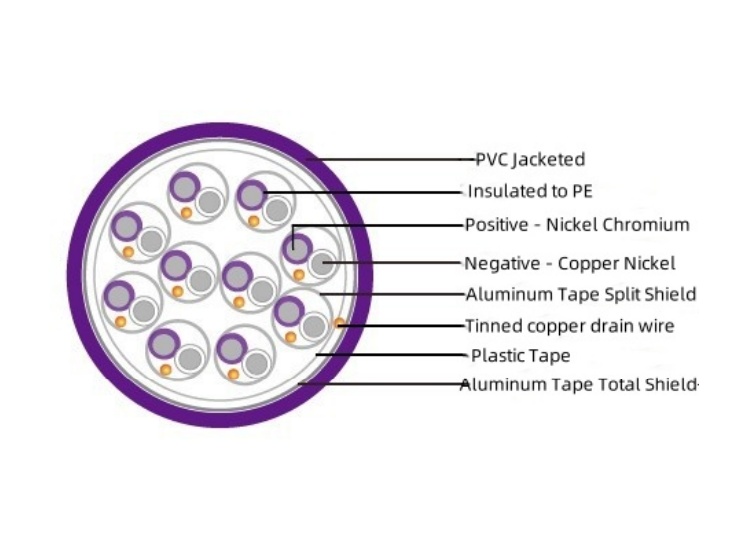

Multi-Pair Split-Shield/Total-Shield Thermocouple Cable

Conductor: Solid

Insulation: PVC, PE, XLPE or LSZH

Sub-shielding: 24μm aluminum or PETP tape plus 0.6mm diameter solid tinned copper drain wire

Winding: At least one layer of plastic tape

Total shield: 24 μm aluminum or PETP tape plus 7 strands of tinned copper drain wire with a cross-sectional area of 0.5 mm².

Jacket: PVC or LSZH

Flame retardation: IEC 60332-1

Temperature range: Operating temperature -30°C to 70°C, Installation temperature -5°C to 50°C.

These cables are used in thermocouple circuits, petrochemical plants, utilities, and industrial plants.

Model: KX, EX, JX, TX, NX, KCA, KCB, RCA, RCB, SCA, SCB, BC

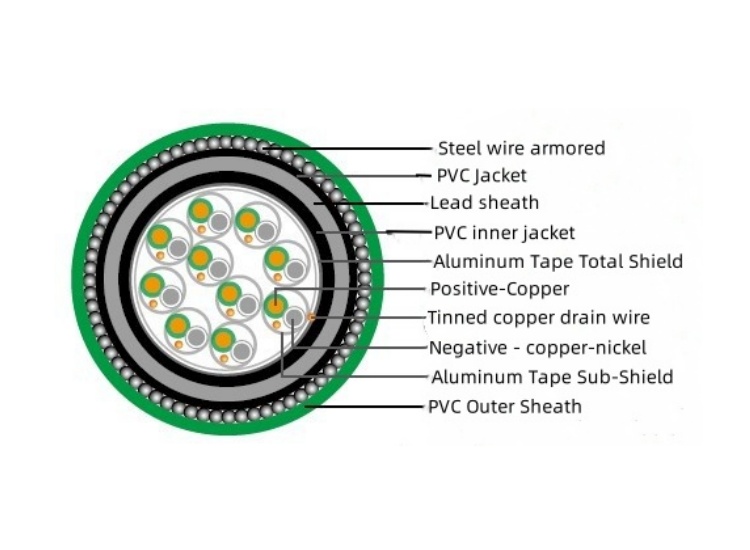

Split-Shield/Total-Shield Armored Lead Sheathed Thermocouple Cable

Conductor: Solid

Insulation: PVC, PE, XLPE or LSZH

Sub-shielding: 24μm aluminum or PETP tape plus 0.6mm diameter solid tinned copper drain wire

Winding: At least one layer of plastic tape

Total shielding: 24 μm aluminum or PETP tape plus 7 strands of tinned copper drain wire with a cross-sectional area of 0.5 mm².

Inner jacket: PE, PVC or LSZH

Lead jacket: lead alloy

Armoring: Galvanized steel wire

Flame retardation: IEC 60332-1

Temperature range: operating temperature -30°C to 70°C. installation temperature -5°C to 50°C.

The cables are connected to different electric thermocouples in cable trays or ducts for industrial process control, refineries, and oil and gas plants. Excellent resistance to corrosion, moisture, and vibration.

Model: KX, EX, JX, TX, NX, KCA, KCB, RCA, RCB, SCA, SCB, BC

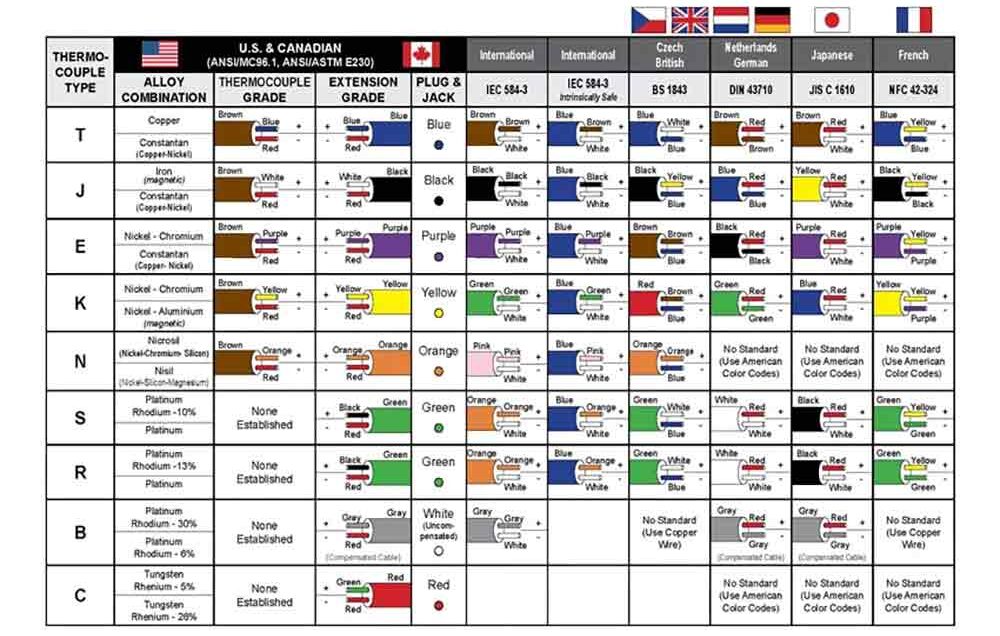

International Thermocouple Wire Colors

Thermocouple extension and compensating cable are pairs of conductors, each made of a different material. The thermocouples must be selected according to the relevant temperature, the operating environment, and the physical characteristics of the components.

These materials are manufactured according to the internationally recognized standard specified in IEC 584 1,2, which is based on the international practical temperature standard ITS 90. The maximum operating temperature depends on the thickness of the thermocouple conductors. Thermocouple types can be subdivided into 2 groups, base metals and rare (precious metals).

A major advantage of thermocouple type J (Iron (JP)/Cuprothal® (JN)) is the ability to work in both oxidizing and reducing atmospheres. Covering the iron with copper prevents corrosion during the shelf life. Although the traditional J-type is still popular in temperature measurement, it is less important in mineral insulated forms due to its limited temperature range – 200C to +750°C. Type J is still mainly in use, based on the widespread use of older instruments calibrated for this type. Their sensitivity rises to 55µV/°C.

The Insulation Material of Thermocouple Cable

The Primary Factors Affecting Thermocouple Life

Temperature: If the temperature rises by 50°C, then the thermocouple life will be shortened by about 50%.

Diameter: If the wire diameter doubles, then the thermocouple life will be extended by 2 to 3 times.

Thermal cycling: If the thermocouple is subjected to thermal cycling from room temperature to over 500°C, then the life of the former will be reduced by about 50% compared to a thermocouple used continuously at the same temperature.

Protection: If the thermocouple is covered with a protective sleeve and placed in a ceramic insulator, then its life will be significantly extended.

Thermocouple Compensation Wire Instructions For Use

Select thermocouple compensation wire to know the thermocouple compensation wire in the ambient temperature and site mining conditions, according to the site ambient temperature situation to choose the appropriate compensation wire sheath, the general ambient temperature in -25 ~ 105 ℃, choose polyvinyl fluoride sheath, the ambient temperature in -60 ~ 205 ℃, choose polytetrafluoroethylene as compensation wire sheath, and in -60 ~ 260 ℃, choose Polytetrafluoroethylene as a thermocouple compensation wire sheath. So in the selection must pay attention to the site mine situation.

| Which insulation material? | Useable temperature range | Application notes |

| PVC | -10°C to 105°C | Good general purpose insulation for ‘light’ environments. Waterproof and very flexible. |

| PFA (Extruded) | -75°C to 250°C | Resistant to oils, acids, other adverse agents and fluids. Good mechanical strength and flexibility. PTFE better for steam/elevated pressure environments. |

| PTFE (taped & wrapped) | -75°C to 250/300°C | Resistant to oils, acids, other adverse agents and fluids. Good mechanical strength and flexibility. |

| Glass fibre (Varnished) | -60°C to 350/400°C | Good temperature range but will not prevent ingress of fluids. Fairly flexible but does not provide good mechanical protection. |

| High temperature glass fibre | -60°C to 700°C | Will withstand temperature up to 700°C but will not prevent ingress of fluids. Fairly flexible, doesn’t provide good protection against physical disturbance. |

| Ceramic Fibre | 0 to 1000°C | Will withstand high temperature, up to 1000°C. Will not protect against fluids or physical disturbance. |

| Glass fibre (varnished) stainless steel overbraid | -60°C to 350/400°C | Good resistance to physical disturbance and high temperature (up to 400°C). Will not prevent ingress of fluids. |

| For maximum accuracy extension cables should be used and terminals and connectors should be of thermocouple materials to maintain continuity. | ||

What is the IEC standard for thermocouples?

The IEC 60584-1 cable standard defines the relationship between the electromotive force (EMF) and temperature for various types of thermocouples, covering commonly used thermocouple types such as K, J, T, E, N, R, S, and B. It establishes precise reference tables and tolerances, describing the expected voltage output of each thermocouple at a specific temperature.

By providing standardized EMF-temperature profiles, it ensures that thermocouples from different suppliers provide consistent and reliable temperature measurement results.

In industrial temperature measurement applications, such as power generation, chemical processing, metallurgy, manufacturing, and laboratory testing, compliance with the IEC 60584-1 standard is crucial. Using thermocouples that conform to this standard helps ensure measurement accuracy, system compatibility, and long-term stability.

Furthermore, IEC 60584-1 provides a common technical basis for the design, testing, and quality control of thermocouple cables and sensors. Manufacturers and users rely on this standard to verify performance characteristics and ensure that thermocouple assemblies meet internationally recognized requirements. This makes IEC 60584-1 an important reference standard for global trade and technical exchange in the field of temperature measurement technology.

What are the different types of thermocouple wires?

1. Selection of Thermocouple Compensation Wire

Thermocouple compensation wire must be used according to the type of thermocouple used and the occasion used to make the correct choice. For example, k-type couples should choose k-type couples compensation wire, according to the use of the occasion, and choose the operating temperature range. Usually, kx working temperature of -20 ~ 100 ℃, a wide range of -25 ~ 200 ℃. The error of the ordinary level is ± 2.5℃, and the precision level is ± 1.5℃.

2. Contact Connection

With the thermocouple terminal 2 joints as close as possible, try to keep the temperature of the two joints the same. Connected with the instrument terminals as much as possible at the same temperature, the instrument cabinet has a fan, and the contact point should be protected from the fan blowing directly to the contact point.

3. Use a Length

Because the thermocouple signal is shallow, microvolt level, if the distance used is too long, the attenuation of the signal and the environment of strong electrical interference coupled, enough to make the signal distortion of the thermocouple, resulting in an inaccurate measurement and control temperature, in control of serious temperature fluctuations.

According to our experience, usually using the thermocouple compensation wire length control within 15 meters is better, if more than 15 meters, it is recommended to use the temperature transmitter for signal transmission. A temperature transmitter is the temperature of the corresponding potential value into DC transmission, strong anti-interference.

4. Wiring

Armored multicore thermocouple cable or compensation wiring must be away from power lines and interference sources. In places where crossing can not be avoided, also as far as possible use the crossway, not parallel.

5. Shielded Compensation Wire

To improve the anti-interference thermocouple connection line, you can use a shielded compensation wire. For the scene with more interference sources, the effect is better. However, the shield must be strictly grounded, otherwise, the shield not only does not play the role of shielding but enhances the interference.

ZMS Cable Service

Wide Cable Product Range

As a professional cable manufacturer and exporter, ZMS supplies a complete range of power cables, control cables, instrument cables, and conductors for global industrial projects.

International Standards & Custom Production

Products are manufactured according to IEC, BS, ASTM, DIN, GB, and other standards, with custom cable design available based on technical requirements.

Professional Technical Support

Free pre-sales consultation, product selection guidance, and one-to-one project solution support for different application environments.

Reliable Delivery Solutions

Optimized packaging and shipping plans to ensure safe delivery while helping reduce transportation risks and costs.

Export Packaging Protection

Wooden drums, cartons, or coils packaging with moisture-proof sealed cable ends and waterproof markings for international transport.