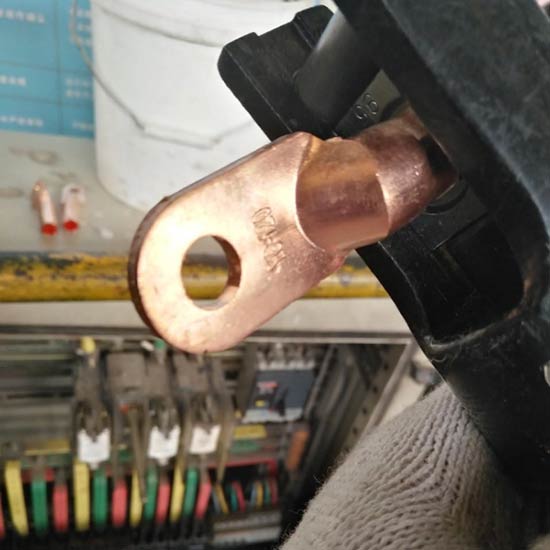

I. Remove Metal Stains, Get A Clean Cable Terminal Lug

Removing metal stains prior to cable connection is an important prerequisite for ensuring cable lug quality.

- Remove metal residues from the conductor surface by wiping.

- Inspect the conductor connection section and remove any visible oxides.

- Ensure that the conductor surface is free of metal residues, otherwise, conductor corrosion in the contact area will occur.

- Ensure that the decontamination of all components has been completed.

II. Strip The Cable Insulation, Strict, And Careful Work

Strip the cable insulation and cable core, pay attention to the stripping size and thoroughness of the stripping, while being careful not to damage the conductor. This is a simple but important note. It is to prevent unnecessary rework in the later formal crimping and exists.

- Use high-quality stripping pliers to completely separate the insulation skin from the cable core, a good tool to make the work easy to handle.

- Be careful not to damage the wire, and the length of the stripped part should be 10% longer than the cable terminal lug or the insertion part of the cable splice tube. Because in the crimping process, the cable terminal lug or cable splice tube will be extended by about 10%.

- When stripping the insulation skin, please do not reduce the size at will.

- Make sure that the crimping parts such as the crimping die or the crimping head are not damaged or dirty. The surface should have the natural metallic luster of a copper or aluminum core. In formal crimping, choosing the right tool with the right method is indispensable. In order to efficiently, quickly, and safely complete the crimping work, select the matching cable lugs and crimping pliers. Mutually compatible tools and components, with professional technology, is the most important point.

Ⅲ. Choose The Right Tools, Components, Bring Perfect Results And Security

Mutually compatible tools and components, professional operating techniques, and a rigorous work ethic are the focus of cable crimping work and are sufficient to bring perfect results.

- Choosing cable terminal lugs, splice tubes and tools from the same manufacturer can significantly improve the reliability of the electrical connection system.

- The reliability test of the electrical connection system certification is based on the overall connection scheme, including cable lugs and tools. Such as IEC, UL, and other international authority certifications, with such certification of the electrical connection scheme can greatly reduce the safety risks of the connection system.

- Select the appropriate tools and the correct way to crimp cable terminal lugs. Including the size of the terminal lug, material, select the corresponding crimping die.

Ⅳ. Crimp The Correct Direction And Starting Point To Ensure That The Project Is Delivered After The Low Rate Of Return

- When crimping cable lugs, start crimping from the connection side toward the cable side.

- For the crimping of the splice tube, start in the middle, otherwise, cracks may eventually form because the material cannot be extended. For example, according to DIN 46235, the number of crimps on the crimped cable lug should be marked on the cable lug and the cable splice tube. The number of crimps for tubular cable terminal blocks is shown in the product brochure.

- Ensure that the crimping process is complete. Complete a complete set of crimping processes is important. Because only in the final part of the crimping process is the final completion of the crimping material required to crimp. This is the only way to ensure proper crimping.

Note: Over-crimping or inadequate crimping can cause a decrease in the reliability of the electrical connection. By following the above points, you will experience the full benefits of using mutually compatible crimping expertise and the correct crimping method to achieve a reliable electrical connection system.

As mentioned above, the preparation work, although inconspicuous, needs to be done carefully and rigorously before the cable crimping work is carried out. And choose a complete set of tools and components from the same brand for the crimping process. The compatibility and safety that comes with this should not be underestimated, coupled with your expertise in operation. This will increase efficiency and ensure delivery standards throughout the crimping process and will guarantee a low return rate.