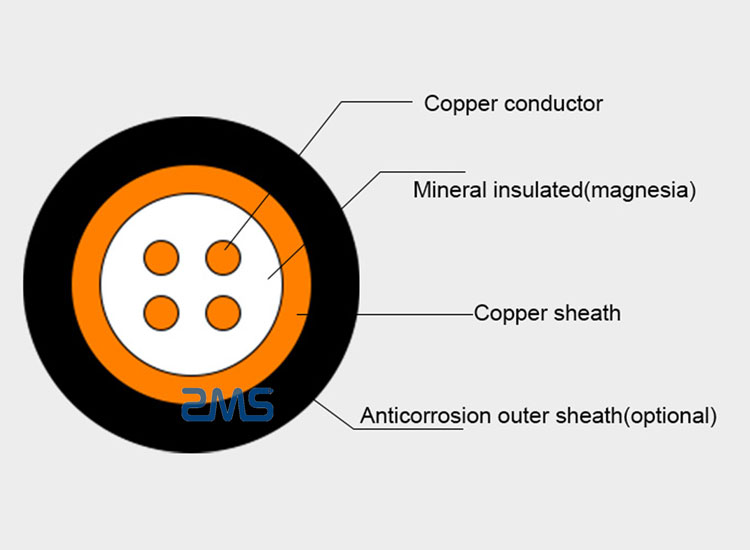

Mineral insulated cable, a copper sheath-wrapped copper conductor core, and magnesium oxide powder as an inorganic insulating material to isolate the conductor and the sheath of the cable, the outermost layer can be selected according to the need for an appropriate protection sleeve.

The Use And Characteristics Of Mineral Insulated Cable

Rigid mineral insulated cable was invented earlier, at the end of the 19th century. The Swiss engineer Arnold Francois Borel on the idea of mineral insulated cable, and received a patent in 1896, 1934-1936, France, and Britain into production to the rapid development.

China also developed in the 1960s, began to be used in the military field, the mid-1980s began industrial production, and was gradually accepted by the construction field in full.

The invention of flexible mineral-insulated fire-resistant cable is relatively late. In the 1970s was born in Switzerland at the Stout Cable Company.

Compared to the traditional BTTZ rigid mineral insulated cable. BBTRZ flexible mineral insulated cable is composed of copper stranded wire, mineral compound insulation, and mineral compound sheath.

It adopts a flexible structure, and the main materials are inorganic, which compensates for the defects of a hard structure, such as being easy to burn and toxic. It also has some advantages that other cables do not have. Such as fire resistance, high load capacity, shock voltage resistance, mechanical damage resistance, halogen-free, and non-toxic. And explosion-proof, waterproof, corrosion-resistant, long life, safety, overload resistance, high-temperature resistance, low cost, and other characteristics.

BBTRZ Fireproof Cable Structure

Cable conductor: There are multiple strands of copper wire twisted together, with good bending characteristics.

Insulation layer: It is made of mineral insulation material, which can withstand temperatures up to 1000 degrees.

Waterproof isolation layer: using polyethylene isolation material.

Mineral filling layer: inorganic mineral material with the advantages of fireproof, fire resistance, high-temperature resistance, and temperature insulation. Heat insulation developed by advanced nanotechnology at home and abroad.

Outer sheath: low smoke, non-toxic, or better, and higher plastic-type material with good anti-corrosion characteristics. Can be selected according to the requirements without the type of material (optional).

The Main Performance of The Mineral Cable

Flexibility

The conductor of the cable adopts the mature stranding technology, and the sheath is made of cross-linked inorganic material, a non-copper tube type. Therefore, not only lightweight and more flexible characteristics. It can avoid the wiring termination problems often encountered when designing and installing rigid mineral-insulated cables (BTTZ).

Fire-Resistant

Since the component materials of the cable are all mineral compounds. It determines the non-combustibility of the cable itself. The product complies with BS and IEC international standards and can withstand burning at 950°C for 3 hours under charged conditions. And guarantees the normal operation of the circuit. Therefore, it can remain unchanged even above the short circuit temperature.

Low Smoke

Smoke emission test according to IEC1034, the test transmittance reaches 80% or more (the standard is 60% ).

Halogen-Free

Since the cable insulation and sheath are inorganic compound materials, there is no usual PVC material. Therefore, even under fire conditions, there is no acidic gas dispersion.

Temperature Resistant

The cable can work at 125°C ambient temperature for a long time, replacing the use of low smoke and halogen-free flame retardant cables with a temperature resistance of 125°C. It can also work below 1080°C for short periods in emergencies.

Corrosion Resistance

The mineral compound material used in the cable is more resistant to corrosion after irradiation and can be laid without any additional measures.

High Load Capacity

Compared with the same cross-section of the cable. The flexible mineral-insulated fireproof cable can not only transmit higher currents but can also withstand larger overloads.

High Mechanical Strength.

Flexible mineral-insulated fireproof cables are made by cross-linking specially developed inorganic compounds through high-energy electron B-rays. The product conforms to BS and IEC international standards. It can withstand 30 consecutive impacts in 15 minutes at 950°C and under energized conditions. Comprehensively overcome the lack of mechanical characteristics of the cable due to the rapid deterioration of material aging characteristics.

Performance Comparison

General wire and cable because the insulation used is organic polymer materials, so it is very easy to carbonize under flame conditions, thus losing its role of insulation. As the main materials of flexible mineral insulation fire cable are all composed of inorganic minerals or mineral compounds, it does not cause fire itself, making it impossible to burn or fuel combustion. These materials generally have a high melting point of more than 1500 ℃, so the fire cable can play a normal function of power transmission even under flame conditions, which is a true sense of the fire cable.

The process structure of flexible mineral insulated fireproof cable products is the same as that of traditional cable, which successfully solves the numerous shortcomings of the product determined by the production process of magnesium oxide copper tube mineral insulated cable. The introduction of this product has become a milestone in the history of fireproof cable development and also accelerated the process of China’s cable technology research and development level to meet the international standard.

1. Traditional rigid mineral insulated cable characteristics

1.1. The copper tube drawing process makes a single continuous length limited; the installation process requires the continuous use of joints, increasing material and labor costs. And the a need for special treatment of the electrical properties of the joint. 2. 35 mm2 and above are all the same.

1.2. 35 mm2 and above are single-core cables, which require many installation procedures and are not conducive to the equalization of electrical parameters of each core.

1.3. The core bar type solid copper conductor is very hard, making its maximum cross-section usually 400 mm2.

1.4. Magnesium oxide powder as an insulation layer, prone to uneven thickness, a slight difference in the process will break through, rated voltage of up to 450/750V.

1.5. BTTZ cable constantly uses special connectors, so special treatment is required to ensure that the flame under the water is a spray to maintain power.

1.6. Once the copper tube shell is on fire, it is directly exposed to the fire temperature, 950°C + 50°C (the plastic outer sheath is instantly burned).

1.7. Metal sheath using a segmental drawing process, large cross-section of 400 mm2, single longest not more than 60 meters. Magnesium oxide pollution to the environment, high cost, and efficiency are difficult to improve.

2. Flexible Mineral Insulated Cable Characteristics

2.1. Improved insulation stability: not only retains the fire resistance characteristics of rigid mineral insulated cable, but also has the characteristics of not absorbing moisture, so the insulation is more stable.

2.2. Increased voltage resistance level: The voltage resistance level can reach 1000V, thus reducing the impact voltage caused by the frequent start-up of inductors and inverter appliances. And accordingly, the service life of the line system is greatly improved.

2.3. Full series: according to the actual needs of users, it can be processed into single-core or multi-core structures, up to 96 cores. This can cover almost all specifications of power cables, flexible cables, and other building cable needs.

2.4. No intermediate joints: The use of mature stranding and cable formation technology, can be produced according to the user’s requirements of fixed length. Not only to reduce the cost of joints, but also to improve and achieve the consistency of the entire line.

2.5. Flexible and easy to install: Because of the traditional cable structure, such as stranded wire and cable formation. The cable is more flexible and does not require special terminal joints, which makes it easier to install and lay.

2.6. Space-saving: The availability of multi-core cables with large cross-sections and lengths eliminates the unnecessary waste of laying space due to multiple arrangements and intermediate joints.

2.7. Public welfare: Due to the improvement of the structure, a large number of minerals and mineral compounds are used, which not only saves copper, magnesium, and other resources, but also saves a lot of energy consumption accordingly, and the public welfare value is also very significant.

Application cases on super high-rise buildings

Case Introduction

Considering the slow reaction speed of people in high-rise buildings, as well as the panic and confusion caused by smoke and lack of electricity supply, the evacuation time of high-rise buildings is largely indeterminate. Therefore, the emergency line and fire alarm alert line become the most important lines in a fire, and the lines must be kept intact.

Liuzhou Diwang International Fortune Center is the tallest building in Guangxi Province and a landmark building in Liuzhou City. With a height of 303 meters and a 73-story all-steel structure. Due to the importance of the project, the fire protection system used Shengyu BBTRZ cable. The series of cables, due to the flexible mineral insulated cable, has a voltage resistance level is 1000V. The design unit is based on the comparison of rigid mineral insulated cable (i.e., copper tube, magnesium oxide insulated cable) and various other types of structures of fire-resistant cables. Decided to use Shengyu BBTRZ flexible mineral insulated series of cables.

Installation and Laying

When the cable is laid openly, it should be supported by a cable bracket, hook, or metal lanyard along the whole length. The maximum span shall comply with the following provisions.

1. To meet the bearing capacity of the support pieces and ensure no damage to the outer layer of the cable and its cable core.

2. So that the cables can be configured neatly with each other.

3. To adapt to the working conditions of the arrangement requirements.

4. Directly support the cable with ordinary brackets (arm bracket), the allowable span of the hanger should be in line with the values specified in the table below.

Flexible mineral-insulated fire-resistant cables with a cross-sectional area of 1.5 mm2 to 600 mm2 for a single core and 1.5 mm2 to 300m2 for multiple cores. In the field of fire-resistant cables. Minimize the investment costs of the user unit and improve the safety and fire performance level of the building.

This type of cable can ensure emergency use after installation, and can also be used as a temperature-resistant 125 ℃ halogen-free flame retardant cable, or a fire-resistant cable. Because of the wide coverage of this series of cables. Not only overcomes the defects of rigid MI cables but also plays to the advantages of flexible MI cables. And provides a practical product for each key project. So that modern engineering in the electrical circuit to achieve a short circuit does not burn, burning does not affect the efficacy. The application cases used in this paper prove that not only the fire alarm and emergency life-saving circuits. And other fire performances can be successfully applied. In the case of high-density current and other special performance requirements, requirements can also be promoted and applied.

FAQ

Q: What is the temperature range of MI cable?

A: Typically –200°C to +950°C depending on the sheath material.

Q: Is the MI cable waterproof?

A: Yes, the metal sheath and sealed ends make it suitable for wet or submerged environments.

Q: Can MI cables be used outdoors?

A: Absolutely. Outdoor-rated mineral insulated cable is widely used in exposed or buried installations.