Overhead Aluminum Cables act as a conduit for the transmission of electricity, transmitting different voltage levels across various distances, environments, and landscapes to provide power where it is needed.

Powerline cables are structurally supported by poles or steel towers designed to keep the wires at a safe height.

This ensures that there is sufficient ground clearance to minimize the risk of interference or damage to live power lines.

So do you know about overhead power lines?

This post provides an overview of what overhead aluminum cables are commonly used.

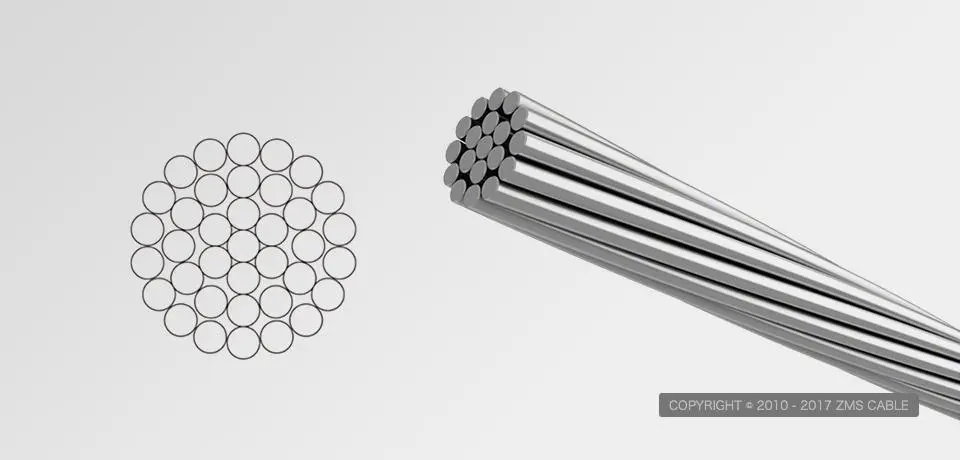

AAC Type Aluminum Power Cables

AAC All Aluminum Conductor is a wire composed of pure aluminum wires, which is suitable for general overhead power transmission lines.

Aluminum core wire, all known as aluminum core power cable, is a kind of cable used for transmitting electric energy, mainly composed of aluminum core, insulation sheath, etc. It is a standard cable symbol.

Applications

The aluminum core wire symbol is used to represent the aluminum core wire in power cables. In the process of engineering design and drawing, the aluminum core line symbol can identify the relevant parameters of the power transmission line, such as conductor material, cross-sectional area, voltage level, and other information, which is convenient for electrical engineers to carry out electrical design according to the needs.

The following table shows the commonly used AAC type aluminum wires and their specification parameters.

| Model Name | Wire Diameter(mm) | Calibre(mm) | Cross-Sectional Area(mm²) |

| AAC-160 | 6.02 | 18.1 | 160 |

| AAC-200 | 6.71 | 20.1 | 200 |

| AAC-240 | 7.62 | 22.9 | 240 |

| AAC-300 | 8.43 | 25.3 | 300 |

AAAC Type Aluminum Wire

With the development of science and technology and the continuous upgrading of the power system, the requirements for conductors are also increasing.AAAC wire, as one of the new wire materials, its superior performance makes is widely used in the power system.

AAAC type aluminum wire all known as all-aluminum alloy wire, is composed of aluminum-magnesium-silicon alloy wire, and the AAC type aluminum wire has better corrosion resistance and strength characteristics.

AAAC cable added a certain proportion of copper, magnesium, silicon, and other elements made of high-performance wire materials, with the following characteristics:

Lightweight

AAAC wire has a low density and weighs about half of a copper wire, which can reduce the burden on transmission towers and cable supports.

Good Electrical Conductivity

Although the conductivity of an AAAC conductor is slightly inferior to that of a copper conductor, it still has high conductivity.

High Corrosion Resistance

AAAC conductors form a dense oxide film on the surface, which protects the inside of the conductor from corrosion.

High Tensile Strength

The wire has a high tensile strength and can withstand large tensile forces.

The following table shows the commonly used AAAC type aluminum wires and their specifications.

| Model Name | Wire Diameter(mm) | Calibre(mm) | Cross-Sectional Area(mm²) |

| AAAC-300 | 8.43 | 25.3 | 300 |

| AAAC-400 | 9.57 | 28.1 | 400 |

| AAAC-500 | 10.71 | 32.7 | 500 |

| AAAC-630 | 12.13 | 36.4 | 630 |

ACSR Type Aluminum Electric Cable

Aluminum-core steel-core cable ACSR is a high-capacity, high-strength stranded conductor typically used for overhead power lines.

The outer strand is high-purity aluminum, selected for its good electrical conductivity, lightweight, low cost, corrosion resistance, and good resistance to mechanical stress.

The center strand is steel, which provides additional strength to help support the weight of the conductor.

Steel is stronger than aluminum, which allows for increased mechanical tension applied to the conductor.

Steel also has lower elastic and inelastic deformation due to lower coefficients of thermal expansion under mechanical loads such as wind ice and current loads.

These characteristics make ACSR sag significantly less than all aluminum conductors. ACSR is designated A1/S1A according to the naming conventions of the International Electrotechnical Commission (IEC) and the CSA Group.

ACSR-type aluminum wire, known as aluminum-core, steel-core-stranded wire, has a high pulling and carrying capacity and is commonly used for high-voltage transmission lines.

The following table shows the commonly used ACSR type aluminum wires and their specifications.

| Model Name | Aluminum Core Diameter(mm) | Diameter of Steel Core(mm) | Cross-Sectional Area (mm²) |

| ACSR-50/8 | 3.07 | 2.95 | 53.2 |

| ACSR-95/15 | 4.57 | 4.65 | 105.0 |

| ACSR-120/20 | 5.17 | 5.27 | 132.1 |

| ACSR-240/40 | 6.86 | 6.96 | 245.1 |

ACAR Type Overhead Aluminum Cables

ACAR (Aluminum Conductor Aluminum Alloy Reinforced) type aluminum wire is known as aluminum core aluminum alloy core string line, is composed of aluminum core and aluminum alloy core of a wire, with high corrosion resistance and strength characteristics, usually used for special occasions of power transmission lines. The following table shows the commonly used ACAR type aluminum wires and their specifications.

| Model Name | Aluminum Core Diameter(mm) | Aluminum Core Diameter(mm) | Cross-Sectional Area (mm²) |

| ACAR-240/40 | 6.86 | 6.96 | 245.1 |

| ACAR-300/45 | 7.62 | 7.72 | 307.2 |

| ACAR-400/45 | 8.43 | 8.53 | 409.7 |

| ACAR-500/45 | 9.14 | 9.24 | 510.5 |

This article introduces the commonly used AAC, AAAC, ACSR, ACAR, and other aluminum wire models and their specifications, different models of aluminum wire for different occasions, the reader can choose according to specific needs.

In the actual application, but also need to consider the power supply capacity of the line, line load, laying environment, equipment operating conditions, and other factors.