Industrial cables are the backbone of modern manufacturing and infrastructure, providing the necessary connections to power machinery, transmit data, and ensure smooth operations. Understanding the different types of industrial cables, their classifications, and their applications is crucial for selecting the right cables for your specific needs. This comprehensive guide by ZMS Cabel will delve into the various types of industrial cables, their key characteristics, applications, and the considerations for choosing the right cables for your industrial operations.

Introduction to Industrial Cables

Industrial cables are designed to meet the demanding requirements of various industrial environments. These cables must withstand harsh conditions, including extreme temperatures, chemical exposure, mechanical stress, and electromagnetic interference. As a result, they are built with robust materials and advanced technologies to ensure reliability and longevity.

Classification of Industrial Cables

Industrial cables can be broadly classified into several categories based on their applications and construction. Here, we explore the main types of industrial cables:

- Power Cables

- Control Cables

- Instrumentation Cables

- Data Cables

- Coaxial Cables

- Fiber Optic Cables

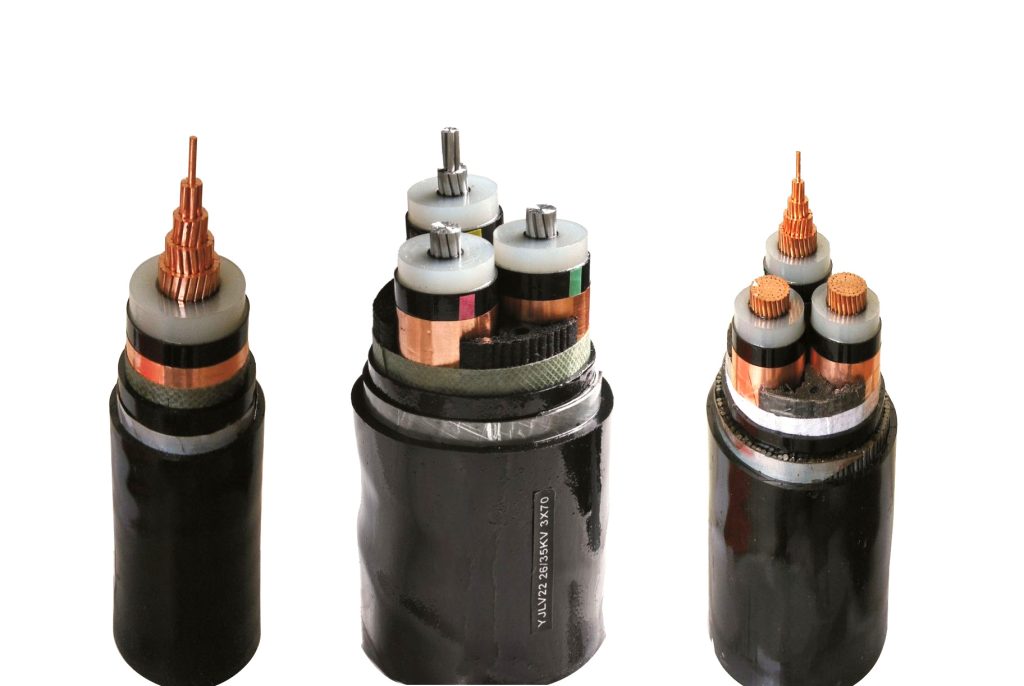

Power Cables

Power cables are used to transmit electrical power from one point to another. These cables are designed to handle high voltages and currents, making them essential for powering machinery and equipment in industrial settings.

Key Characteristics:

- Conductor Material: Typically made of copper or aluminum.

- Insulation: PVC, XLPE (cross-linked polyethylene), or rubber.

- Voltage Rating: Can range from low voltage (up to 1kV) to high voltage (above 35kV).

Applications:

- Power distribution within industrial facilities.

- Connecting transformers to electrical panels.

- Supplying power to heavy machinery and equipment.

Control Cables

Control cables transmit control signals and data between different components of an industrial system. These cables are designed for flexibility and durability, ensuring reliable performance in control applications.

Key Characteristics:

- Conductor Material: Copper.

- Insulation: PVC, PE (polyethylene), or rubber.

- Shielding: Often shielded to protect against electromagnetic interference.

Applications:

- Connecting control panels to machinery.

- Automation systems.

- Conveyor systems.

Instrumentation Cables

Instrumentation cables are designed to carry low voltage signals from sensors and instruments to control systems. These cables ensure accurate signal transmission, critical for monitoring and controlling industrial processes.

Key Characteristics:

- Conductor Material: Copper.

- Insulation: PE, PVC, or EPR (ethylene propylene rubber).

- Shielding: Multiple layers of shielding to prevent signal interference.

Applications:

- Process control systems.

- Data acquisition systems.

- Industrial automation.

Data Cables

Data cables transmit data between computers, networking devices, and other digital equipment. These cables are essential for industrial communication and networking.

Key Characteristics:

- Conductor Material: Copper.

- Insulation: PE, PVC, or Teflon.

- Shielding: Shielded or unshielded twisted pairs (STP or UTP).

Applications:

- Ethernet networking.

- Industrial automation networks.

- Data centers.

Coaxial Cables

Coaxial cables are used for transmitting high-frequency signals with minimal loss. These cables consist of a central conductor, insulating layer, metallic shield, and outer insulating layer.

Key Characteristics:

- Conductor Material: Copper.

- Insulation: Foam PE or Teflon.

- Shielding: Braided copper or aluminum.

Applications:

- CCTV systems.

- Industrial communication systems.

- High-frequency signal transmission.

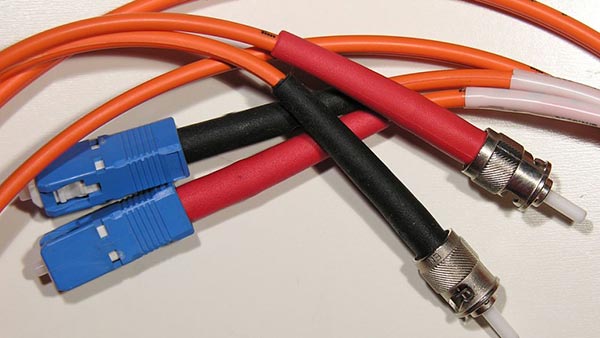

Fiber Optic Cables

Fiber optic cables use light to transmit data over long distances with minimal signal loss. These cables are immune to electromagnetic interference and provide high-speed data transmission.

Key Characteristics:

- Core Material: Glass or plastic fibers.

- Cladding: Material with a lower refractive index than the core.

- Jacket: PVC or other protective materials.

Applications:

- Industrial networking.

- High-speed data transmission.

- Communication systems.

Applications of Industrial Cables

Industrial cables are used in a wide range of applications across various industries. Here, we explore some of the key applications:

Manufacturing

In manufacturing, industrial cables are used to power machinery, control automated systems, and transmit data for monitoring and control purposes.

Key Applications:

- Powering production lines and machinery.

- Connecting control panels to sensors and actuators.

- Data transmission for monitoring and control systems.

Oil and Gas

The oil and gas industry relies on robust industry electric cables to ensure the safe and efficient operation of exploration, drilling, and production processes.

Key Applications:

- Powering drilling rigs and pumps.

- Connecting control systems to sensors and valves.

- Data transmission for monitoring and control.

Mining

Mining operations require industrial cables that can withstand harsh conditions, including extreme temperatures, moisture, and mechanical stress.

Key Applications:

- Powering mining equipment and machinery.

- Connecting control systems to sensors and actuators.

- Data transmission for monitoring and control systems.

Construction

The construction industry uses industrial cables to power equipment, control systems, and transmit data for various applications.

Key Applications:

- Powering construction machinery and equipment.

- Connecting control systems to sensors and actuators.

- Data transmission for monitoring and control systems.

Telecommunications

Telecommunications rely on industrial cables to transmit data and signals over long distances with minimal loss and interference.

Key Applications:

- High-speed data transmission.

- Connecting communication equipment.

- Transmitting signals for broadcasting and networking.

Renewable Energy

The renewable energy industry uses industrial cables to connect power generation sources, such as solar panels and wind turbines, to the grid and control systems.

Key Applications:

- Power transmission from renewable energy sources.

- Connecting control systems to sensors and actuators.

- Data transmission for monitoring and control systems.

Key Considerations for Choosing Industry Cables

Choosing the right industrial cables is critical for ensuring the reliable and efficient operation of your industrial systems. Here are some key considerations to keep in mind:

Voltage and Current Ratings

Ensure the cable you choose can handle the required voltage and current levels for your application. Using a cable with insufficient ratings can lead to overheating, electrical failures, and safety hazards.

Environmental Conditions

Consider the environmental conditions in which the cable will be used. Factors such as temperature, humidity, chemical exposure, and mechanical stress can impact the performance and longevity of the cable.

Flexibility and Bend Radius

In applications where cables need to be routed through tight spaces or around obstacles, flexibility, and bend radius are important factors. Choose cables that can withstand the required bending without damage.

Shielding and Interference

In environments with high levels of electromagnetic interference, choose cables with appropriate shielding to protect against signal loss and interference. Shielded cables are essential for data and control applications.

Durability and Lifespan

Consider the durability and expected lifespan of the cable. Choose cables made from high-quality materials that can withstand the demands of your application and provide long-term reliability.

Compliance with Standards

Ensure the cables you choose comply with relevant industry standards and regulations. Compliance with standards such as UL, CSA, and IEC ensures the cables meet safety and performance requirements.

Conclusion

Industry power cables are essential components in a wide range of applications, from powering machinery and transmitting data to controlling automated systems. Understanding the different types of industrial cables, their classifications, and their applications is crucial for selecting the right cables for your specific needs.

By considering factors such as voltage and current ratings, environmental conditions, flexibility, shielding, durability, and compliance with standards, you can ensure you choose the right cables to support the reliable and efficient operation of your industrial systems.

Investing in high-quality industrial cables not only enhances the performance and longevity of your equipment but also contributes to the overall safety and efficiency of your operations. Whether you are involved in manufacturing, oil and gas, mining, construction, telecommunications, or renewable energy, selecting the right industrial cables is a critical step toward achieving your operational goals and maintaining a competitive edge in your industry.