NEK 606 is an international cable standard developed by the Norwegian Electrical Standards Council for cables used in ships, offshore platforms and other harsh environments. This paper presents a complete analysis of NEK 606 standard cables in terms of structure, applications, advantages and technical features.

Table of Contents

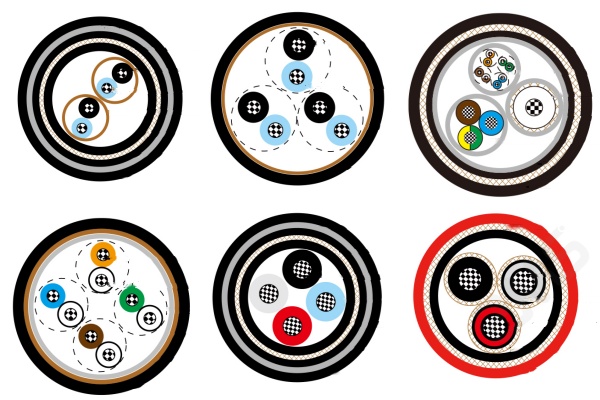

ToggleInfrastructure for NEK 606 Standard Cables

| Structural Layer | Material / Characteristics |

| Conductor | High purity copper conductor, stranded construction to ensure flexibility and conductivity. |

| Insulation | Cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR), high temperature and chemical resistant. |

| Inner Sheath | Low Smoke Zero Halogen (LSZH) material, fire resistant and environmentally friendly. Armouring Galvanized steel wire or copper tape armoring provides mechanical protection and tensile strength. |

| Outer Sheath | Oil and chemical-resistant polyvinyl chloride (PVC) or neoprene (PCP) for harsh environments. |

NEK 606 Cable Technical Data

| Rated Voltage | typically 0.6/1 kV for low voltage power systems. |

| Temperature Range | -40°C to +90°C (+120°C for short periods), adapted to extreme temperatures. |

| Fire Resistance | conforms to IEC 60332 flame retardant standard, some models meet IEC 60331 fire resistance requirements. |

| Oil Resistance | tested to EN 60811-404 for oil resistance, suitable for use in oily environments. |

| Mechanical Strength | The armor layer provides excellent resistance to compression, tension, and impact. |

Conductor Cross Section Area & Current Carrying Capacity

| Conductor Cross Section (mm²) | Approximate Outer Diameter (mm) | Approximate Weight (kg/km) | Load Capacity (A) – In Air | Capacity (A) – Buried |

| 1.5 | 8.5 | 150 | 20 | 18 |

| 2.5 | 9.5 | 200 | 27 | 24 |

| 4 | 11 | 300 | 37 | 32 |

| 6 | 12.5 | 400 | 47 | 41 |

| 10 | 15 | 600 | 64 | 56 |

| 16 | 17.5 | 900 | 85 | 75 |

| 25 | 20 | 1300 | 110 | 95 |

| 35 | 22.5 | 1700 | 135 | 115 |

| 50 | 25 | 2300 | 165 | 140 |

| 70 | 28 | 3100 | 205 | 175 |

| 95 | 31 | 4100 | 250 | 210 |

| 120 | 34 | 5100 | 290 | 240 |

| 150 | 37 | 6200 | 330 | 275 |

NEK 606 Cable Performance Parameters

| Performance Categories | Parameters | Value/Description |

| Electrical Performance | rated voltage | 0.6/1 kV |

| Insulation resistance | ≥ 20 MΩ-km (at 20°C) | |

| Pressure Resistance Tests | 3.5 kV AC (5 minutes) or 8.5 kV DC (5 minutes) | |

| capacitors | ≤ 0.5 µF/km (at 1 kHz) | |

| inductors | ≤ 0.5 mH/km (at 1 kHz) | |

| Mechanical Properties | Conductor tensile strength | ≥ 10 N/mm² |

| Conductor elongation | ≥ 150% | |

| Armor tensile strength | ≥ 300 N/mm² (galvanized steel wire) | |

| Sheath wear resistance | Abrasion tested to EN 50396 | |

| Minimum Bend Radius | 6 x cable O.D. (fixed installation) or 10 x cable O.D. (mobile installation) | |

| Environmental Performance | Temp. range | -40°C to +90°C (up to +120°C for short periods) |

| oil-proof | Passes EN 60811-404 oil resistance test | |

| Chemical resistance | Resistant to acids, alkalis and salt spray (according to IEC 60811) | |

| UV resistance | Passes EN 50396 UV resistance test | |

| Fire performance | Complies with IEC 60332 (flame retardant) and IEC 60331 (fire resistant) | |

| environmental | Low Smoke Zero Halogen (LSZH) materials, RoHS and REACH compliant |

Note:

Electrical Properties: Ensure the safe operation of cables at rated voltage, while also meeting insulation, voltage resistance, and signal transmission requirements.

Mechanical Properties: Provide excellent tensile, compressive,e and abrasion resistance to adapt to complex installation environments.

Environmental Performance: Ensure the long-term reliability of the cable under extreme temperatures, oil, chemical corrosion, and UV exposure.

Common Categories - BFOU RFOU

BFOU and RFOU are cable categories under the NEK 606 standard and are mainly used for offshore oil and gas platforms and marine applications:

BFOU (Fire Resistant Offshore & Utility Cables): Fire resistant, low smoke, and halogen-free, for high-security environments such as emergency power and control systems.

RFOU (Flame Retardant Offshore & Utility Cables): Flame retardant, mud resistant, suitable for regular offshore power and control applications.

Specific models typically include BFOU 0.6/1kV, BFOU 3.6/6kV, RFOU 0.6/1kV, RFOU 3.6/6kV, and others.

| Cable Type | Voltage Rating | Standard | Main Application | Key Features |

| BFOU 250V | 250V | NEK 606, IEC 60331 | Instrumentation cable | Fire-resistant, Low Smoke Zero Halogen (LSZH) |

| BFOU 0.6/1kV | 0.6/1kV | NEK 606, IEC 60331 | Power & control cable | High fire resistance for critical systems |

| BFOU 3.6/6kV | 3.6/6kV | NEK 606, IEC 60331 | Medium voltage applications | High-temperature resistant, LSZH |

| RFOU 250V | 250V | NEK 606, IEC 60332-3 | Instrumentation cable | Mud-resistant, LSZH |

| RFOU 0.6/1kV | 0.6/1kV | NEK 606, IEC 60332-3 | Power & control cable | Flame-retardant, corrosion-resistant |

| RFOU 3.6/6kV | 3.6/6kV | NEK 606, IEC 60332-3 | Medium voltage applications | High mechanical strength, suitable for harsh environments |

ZMS Advises You How to Choose

Environmental conditions: choose suitable sheath material according to temperature, oil, chemical corrosion, and other environmental factors.

Mechanical requirements: choose the armored model on the occasion where tensile and compressive resistance is required.

Fire rating: Select the model that complies with IEC 60331 or IEC 60332 according to the project requirements.

NEK 606 standard cables are ideal for marine, offshore, and industrial applications due to their excellent electrical properties, mechanical strength, and environmental suitability. Its technical parameters are by international standards and it meets the requirements for power transmission in harsh environments. For more detailed specifications or customized solutions, please feel free to contact the ZMS cable manufacturer for technical support.