BS 6622 aluminum armored cable is a medium-voltage (MV) power cable designed to BS 6622 and suitable for voltages from 3.8/6.6kV to 19/33kV. It features cross-linked polyethylene (XLPE) insulation, a polyvinyl chloride (PVC) sheath, and aluminum wire armor (AWA) or steel wire armor (SWA) protection, making it ideal for industrial power transmission and underground installations.

Table of Contents

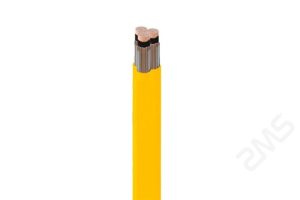

ToggleBS 6622 Aluminium Cable Structure

Conductor: Stranded Aluminium to BS EN 60228 Class 2

Insulation: XLPE (Cross-Linked Polyethylene)

Insulation Screen: XLPE Semi-conducting layer

Metallic Screen: Copper tape or wire screen

Armour: AWA (for single-core) / SWA (for multi-core)

Sheath: PVC or PE outer sheath (black)

Technical Data (3 Core 11kV XLPE Aluminium Cable)

| Specification | Value |

| Voltage Rating | 6.35/11kV, 3.8/6.6 (7.2)kV |

| Conductor Material | Aluminium |

| Number of Cores | 3 |

| Conductor Size | 70 mm² – 300 mm² |

| Insulation | XLPE (Cross-Linked Polyethylene) |

| Armour Type | SWA / AWA |

| Operating Temperature | -15°C to +90°C |

| Test Voltage | 12.5kV AC for 15 min |

| Temperature Rating | Maximum operating temperature: 90°C Maximum short circuit temperature: 250°C |

| Standards | BS 6622, IEC 60502-2 Flame Retardant according to IEC/EN 60332-1-2 |

Applications of BS 6622 Medium Voltage Cables

BS 6622 Aluminium Armoured Cables are used in a wide range of medium voltage electrical systems where consistent power transmission and mechanical protection are required.

Typical applications include:

- Power distribution between substations and local grids

- Underground electrical systems

- Renewable energy facilities (solar and wind farms)

- Industrial plants, refineries, and manufacturing zones

- Public infrastructure such as airports, tunnels, and rail systems

- Fixed installations in cable ducts, trays, or directly buried systems

With XLPE insulation and AWA/SWA armouring, these cables ensure long-term stability even under demanding mechanical and thermal conditions.

Advantages of BS 6622 Aluminium Armoured Cable

Lightweight & Economical: Compared to traditional copper conductors, aluminum conductors offer significantly lower weight, facilitating installation and reducing costs.

Strong Mechanical Protection: AWA and SWA armored construction layers effectively protect against external damage, making the cable suitable for direct burial and industrial environments.

Excellent Electrical Performance: The XLPE insulation structure supports high current-carrying capacity and low dielectric loss.

Chemical Resistance & Moisture Protection: The PVC or PE outer sheath offers excellent corrosion resistance, resisting UV radiation and oil contamination.

Thermal Stability: The XLPE insulation layer can operate continuously at 90°C with a short-circuit temperature up to 250°C.

Flexible Installation: Suitable for indoor, outdoor, or underground installations, ensuring project compatibility.

What is BS 6622?

So, what is the BS 6622 cable standard?

BS 6622 is a British standard that specifies the construction, testing, and performance requirements for cross-linked polyethylene (XLPE) insulated armored power cables with rated voltages from 3.8/6.6kV to 19/33kV. This standard ensures the electrical reliability, insulation integrity, and safety of medium-voltage (MV) power transmission and distribution systems.

Cables manufactured according to this standard are generally suitable for industrial and utility applications, ensuring consistent quality across cables from different manufacturers.

What is the difference between BS7835 and BS6622?

After explaining what BS6622 cable is, we have also listed its differences from BS7835 standard cable to help you understand the differences between them and choose a more suitable cable.

Although BS 6622 and BS 7835 cover similar voltage ranges and construction principles, they differ mainly in sheath materials and flame performance requirements.

| Comparison | BS 6622 | BS 7835 |

| Sheath Material | PVC or PE | LSZH (Low Smoke Zero Halogen) |

| Flame Retardance | Standard | Enhanced (low smoke, halogen-free) |

| Typical Environment | Outdoor or industrial areas | Public spaces and enclosed installations |

| Armour Type | AWA or SWA | AWA or SWA |

| Purpose | General medium voltage use | Fire-safe applications (rail, tunnels, buildings) |

In short, BS 6622 is the standard PVC or PE sheathed version, while BS 7835 specifies LSZH (Low Smoke Zero Halogen) materials for enhanced fire performance — making it ideal for installations where smoke and toxic emissions must be minimized.

We also welcome customers to contact us for assistance in selecting the right cable!