With the development of the cable industry, the advantages of copper-core cable are more. Copper-core cables occupy an absolute advantage over aluminum-core cables in the cable market. However, the high price of copper-core cable also caused an increase in production costs, and also bad construction. The aluminum-core cable as a cable industry “foreign army” emerged, in the market’s favor.

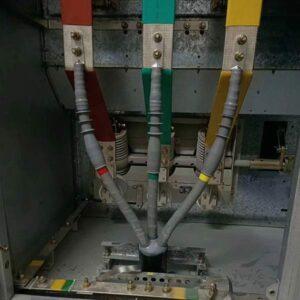

terminal lugs

Standards For Cable and Terminal Lug Crimping Specifications

I. Remove Metal Stains, Get A Clean Cable Terminal Lug

Removing metal stains prior to cable connection is an important prerequisite for ensuring cable lug quality.

- Remove metal residues from the conductor surface by wiping.

- Inspect the conductor connection section and remove any visible oxides.

- Ensure that the conductor surface is free of metal residues, otherwise, conductor corrosion in the contact area will occur.

- Ensure that the decontamination of all components has been completed.

Why Use Ring Terminal Lug with Insulation?

Ring Terminal Lug With Insulation: Simple Installation, Cheap Cable lug is often used for cable end connection and continuation. Which can make the connection between cable and electrical appliances more firm and safer. It is a common material for building, electrical equipment, electrical connection and so on. Generally, when the … Read more

How Are The Lugs And Cables Tightly Welded?

Wire nose is also a very commonly used hardware in electric power systems. According to the industry, it is generally called a cable terminal. When connecting electricity, the more important step is to connect the cable lug with the cable. If the cable cannot be compacted, it is inevitable and … Read more