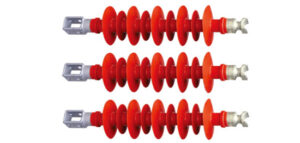

Composite insulators can effectively use narrow corridors to open voltage and transmit electricity, and are suitable for technical transformation of urban network. They can reduce the height of poles and towers and save a lot of manpower, material resources and financial resources. Due to the high bending strength of composite material insulators, it can prevent the cascading fracture accidents that are prone to porcelain cross arm, and it is an irreplaceable product for porcelain cross arm. In addition, the composite insulator is small in size, light in weight, shockproof and impact resistant, and does not require manual cleaning, which provides a guarantee for safe operation.

INFORMATION

Welcome to the ZMS CABLE information blog, here is the cable industry knowledge sharing and technology popularization of the professional world. In this section, we focus on cable technology, product applications, and industry knowledge, carefully crafting a series of easy-to-understand and practical content, to provide readers with authoritative technical support and comprehensive industry interpretation.

What are the Functions of Electricity Insulators?

A lot of disk-shaped insulators are hung on one end of the high-voltage wire connection tower to increase the creepage distance, usually made of glass, ceramic or composite materials, called electricity insulators.

In order to prevent dust and other pollution from adhering to the surface of the insulator, a path is formed to be broken down by the voltage across the insulator, that is creepage. Therefore, increase the surface distance, that is the creeping distance, and the distance along the insulating surface that is the leakage distance is called the creeping distance. Climbing distance = surface distance / the highest voltage of the system. Depending on the degree of pollution, a crawl distance of 31 mm/kV is generally used in heavily polluted areas.

Characteristics And Benefits Of Cable Terminal Lug

When the cable lug under take the cable engineering project around small, and medium scale. Power cable terminal connection workable to provide efficient and effective connections inside cable connection projects.

When you are new to the market place and you are looking to get a cable terminal lugs, you more than likely want to find out the huge benefits and characteristics of cable terminal lugs. It’s far better to become well informed than regretting once the purchase. This post will shed more light around the characteristics and great things about cable lugs.

Why Can’t High-Voltage Cables Be Buried in the Ground?

Ultra-high voltage transmission refers to the use of 500 kV-1000 kV voltage levels to transmit electrical energy. If the 220kV transmission indicator is taken as 100%, the relative investment per kilometer of UHV transmission, the relative cost of 100 kilometers per kilowatt-hour of electricity transmission, and the consumption of metal materials will be greatly reduced. In this way, the utilization rate of the line corridor has been significantly improved.

In our daily life, we can often see overhead ultra-high voltage transmission projects. However, have you ever thought about this question: Why can’t all high-voltage cable be buried underground like urban underground cables?

What are the Advantages of Cold Shrink Cable Termination?

The Difference Between Cold Shrink Termination and Heat Shrink Termination:

1. The difference between the ground wire connection methods: Cold-shrinkable cable accessories use constant force springs. The heat shrinkable cable accessories need to be soldered when using a ground wire.

2. The difference of the shrinkage method: The plastic support strip of the core part of the cold-shrinkable cable accessory shrinks naturally. The heat-shrinkable cable accessory needs to be heated by fire to shrink the low-voltage cable termination.

How to Choose the Cables in the High-Voltage Electrical Distribution Cabinet?

As a member of the electric power industry, electric wires and cables are an indispensable part of our daily work. Wires and cables are used to transmit electric energy, information, and realize the conversion of electromagnetic energy. The insulated cable is composed of one or more insulated cores, and their … Read more

Why Use Ring Terminal Lug with Insulation?

Ring Terminal Lug With Insulation: Simple Installation, Cheap Cable lug is often used for cable end connection and continuation. Which can make the connection between cable and electrical appliances more firm and safer. It is a common material for building, electrical equipment, electrical connection and so on. Generally, when the … Read more

What is a Wire Duct?

Wire ducts, also known as cable trays, wire troughs, wiring troughs, and wire troughs (different from place to place). They are electrical appliances used to standardize power lines, data lines, and fix them on the wall or ceiling. There are two kinds of plastic material and metal material in generally, … Read more

What is the Difference Between a Cold Shrinkable Cable Joint and a Heat Shrinkable Cable Joint?

Structure The cross-linked cable is composed of the outer sheath, metal armor, inner sheath, filler, copper shielding layer, outer semiconducting layer, insulating layer, inner semiconducting layer, conductor, money core of the cable. Therefore, what kind of cable structure needs to have what kind of material and technology of cable accessories … Read more

Why are Nylon Materials Used in Cable Waterproof Glands?

Reasons for using nylon material for waterproof glands ● Good sealing performance, safe and reliable. ● Nylon pipe fittings are suitable for water contact for a long time, no corrosion, no rust, no poison. ● Adapt to temperature -40° to 135°. ● The service life is more than 50 years. … Read more