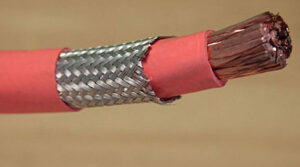

According to different occasions, the cable structure is also different. In the occasion of shielding interference, shielded cables are widely used. So when choosing shielded cables, should you choose copper wire shielding or copper tape shielding?

The function of the shielding layer is mainly to protect the current or signal from external electromagnetic interference. And it avoid the electromagnetic field generated by itself during use to the surrounding environment and current flow failure.

INFORMATION

Welcome to the ZMS CABLE information blog, here is the cable industry knowledge sharing and technology popularization of the professional world. In this section, we focus on cable technology, product applications, and industry knowledge, carefully crafting a series of easy-to-understand and practical content, to provide readers with authoritative technical support and comprehensive industry interpretation.

One Minute To Understand The Role Of Cable Shielding

The outer layer of the wire and cable is generally rubber or rubber composite sheath, the function of this layer is to insulate, but also to protect the cable from damage.

The cable is divided into high-voltage or low-voltage cables. If it is high-voltage, there will be a layer of resin-like filler inside, which serves as insulation. In high-voltage cables, this layer is an important part of insulation. There is no such thing in low pressure. Then there will be something like ribbon wrapped inside, which is to fix each core of the cable and fill the gap in the middle.

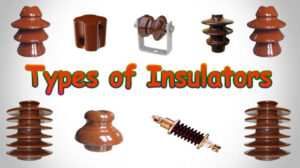

Must-see: The Use and Classification of Cable Insulators

Cable Insulator is a special insulation control, which plays an important role in overhead transmission lines. Mainly used for the connection of wires and cables. For example, a lot of disk-shaped insulators are hung on one end of the high-voltage wire connection tower to increase the creepage distance, usually made of glass or ceramic, which is the insulator.

35kv Cold-Shrinkable and Heat-Shrinkable Cable Accessories in Wind Farms

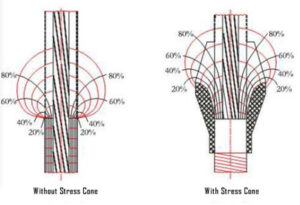

The development of new energy in China is now on the fast track, and wind power generation accounts for a significant share of it. Many wind farms are built on the grasslands of Inner Mongolia, and the 35kV collector lines of wind farms are laid using direct burial cables to protect the grassland vegetation and the overall appearance of the grassland. From the operation situation, the cable intermediate head has the phenomenon of discharge.

How Important are Cold-Shrinkable Cable Accessories in the Cable Line?

Cold-shrinkable cable accessories are a kind of prefabricated cable accessories that can be constructed at room temperature without heating. The cold-shrinkable power cable accessories are made of imported liquid silicone rubber. After installation, they always maintain a proper radial pressure on the cable body. The interface characteristics are relatively good, and there will be no creepage breakdown due to cable operation. The stress control part is integrated with the main insulation, which effectively solves the problem of electric stress concentration at the outer shielding section of the cable and ensures reliable insulation. It is a very important cable accessory.

Common Causes Of Cable Termination Heating

1、High Voltage Cable Termination Structure and Insulation Mdium

1.1 Overall Structure

High-voltage cable terminations can be divided into porcelain sleeve type, composite sleeve type, integral prefabricated type, GIS termination, etc. Their core structure is similar. The description here is based on the ceramic sleeve type cable termination structure as an example.

Figure 1 Typical structure of porcelain sleeve type cable termination

1—Outlet fittings, 2—Wiring post, 3—Shield cover, 4—Insulation filler, 5—Porcelain sleeve, 6—Stress cone protective cover, 7—Stress cone, 8—cone support, 9—support insulator, 10— Tailpipe

Briefly Describe the Basic Knowledge of Cable Accessories

Cable accessories refer to the intermediate connections and terminal connections of various cables in the cable line, which together with the cables form a power transmission network. With the continuous development of cable manufacturing technology, cable accessories have gone through several stages, such as cast cable accessories, wrapped cable accessories, heat shrinkable cable accessories, prefabricated cable accessories and cold shrinkable cable accessories. At present, the most widely used are heat shrinkable cable accessories, prefabricated cable accessories and cold shrinkable cable accessories. Next, let’s take a look at it in detail.

The Flame Retardant Grade of Cable is Related to the Safety of Life. Have You Chosen the Right One?

With the development of wire and cable production technology, there are more and more types of wires and cables. Even cables of the same kind have different specifications and grades. However, their requirements for fire resistance and flame retardancy have been ignored by people, and their grades are not up to standard, which easily lays huge hidden dangers for fires. If all the highest levels are used, there will be a little “waste”. Then several elements of the flame retardant grade of wires and cables should be considered in the project engineering design? Here are some suggestions for you, hoping to help you.

Can the Waterproof Piercing Clamp be Used Directly Under Water?

It should be said that the piercing clamp is a relatively large choice in the implementation of the current cable and wire branching program. However, in many branching programs, most people will have a question in their minds, is the piercing clamp waterproof? Can the waterproof piercing clamp be directly buried or used underwater? Let’s take a practical case for analysis.

Do You Know the Difference Between Power Cables and Control Cables?

Generally, power cables are within 5 cores. They are generally used for high-voltage power. The number of cores of control cables is relatively large. Sometimes customer requirements are different, generally to 37 cores, but there are more cores.