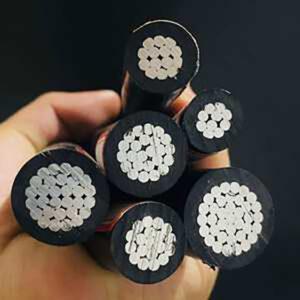

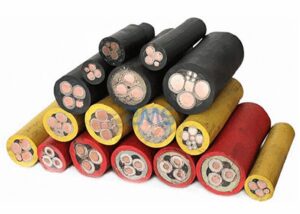

An Overhead insulated cable is a cable made of special structural material with an outer sheath.

Its insulation layer is affected by the external environment during line operation, such as temperature, humidity, and other factors that can cause certain deformation or aging of the cable, resulting in certain defects.

And in the normal operation process, due to the conductor to withstand the influence of external environmental factors and its maintenance, its external state can be maintained for some time.

Therefore, it is necessary to take measures during cable operation to ensure its good working condition and safe operation.